The State of Circular Innovations in the Indian Fashion and Textile Industries

Executive Summary

The Indian fashion and textile industry contends with challenges that mirror those in the global landscape. The importance of the industry to India’s socioeconomic advancement cannot be overemphasised. It currently employs over 45 million people, contributes 15% of the country’s export earnings and 7% of the country’s industry output.

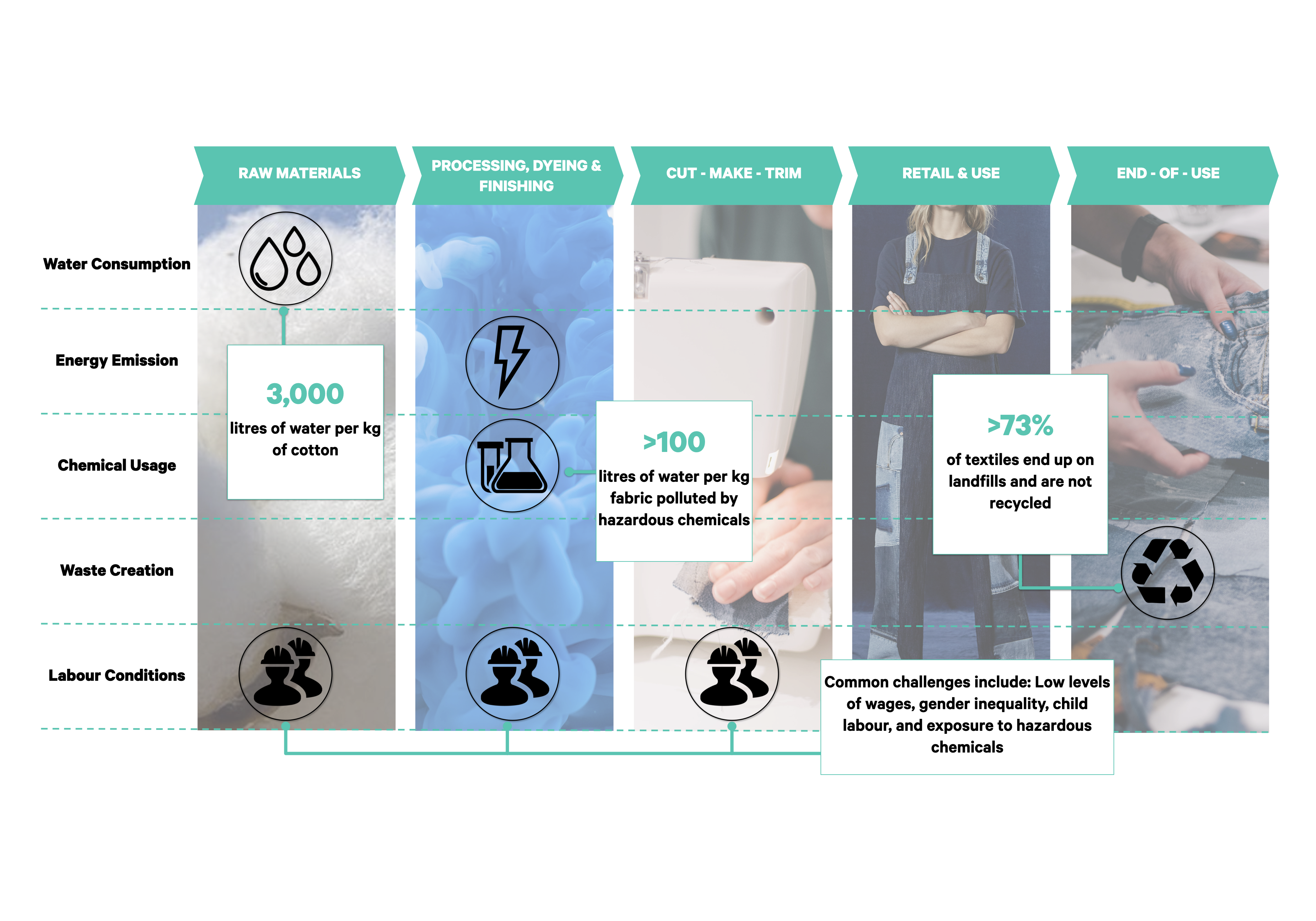

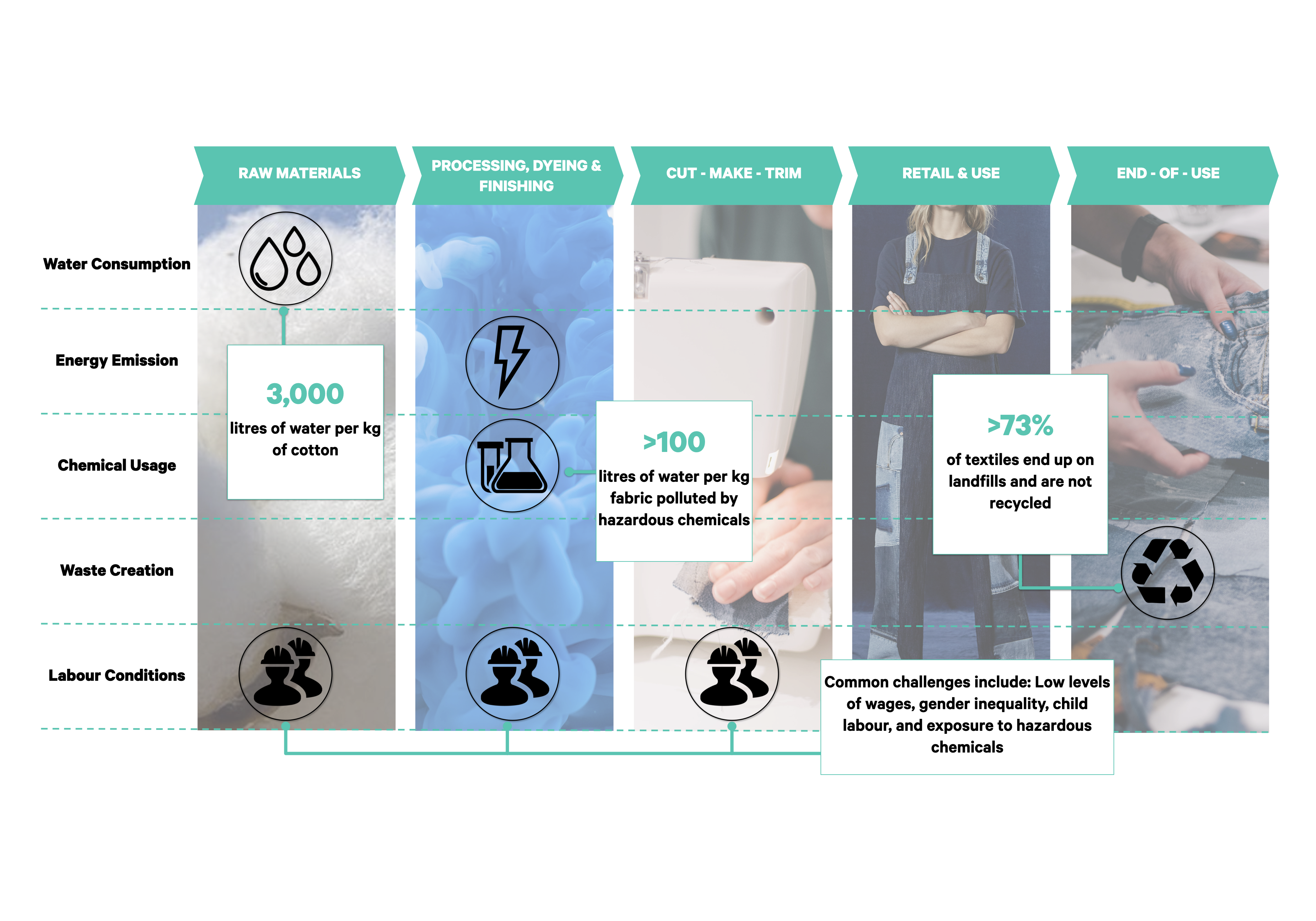

Challenges and Opportunities Across the Supply Chain

The fashion industry is valued at $2 trillion1 and contributes to over 2% of global GDP but the industry’s supply chain accounts for 4% of global total greenhouse gas (GHG) emissions2. The direct impact of this complex, global, supply chain is most felt in terms of water consumption, energy emissions, waste creation and chemical usage as evident in the supporting graphic:

Raw Materials

The textile supply chain begins with raw materials, which are used as feedstock for the production of fibre, yarns and fabric. It is estimated that more than half3 of the environmental footprint of the textile and apparel industry is created in this stage. For the most commonly used fibres: polyester (51.5%4) and cotton (24.4%5), the C02 emissions are estimated at 1.7-4.5 kg and 0.5-4.3 kg per T-Sshirt of the fibres respectively6. This brings about the need for alternative, lower impact new materials or improved manufacturing processes..

Wet and Dry Processing

During the processing stage, the fibres, yarns, fabrics or garments go through multiple steps to achieve the performance and aesthetic properties desired by the brand and its consumers. These steps can be broadly categorised into pretreatment, dyeing, printing and finishing treatments.

Cut-Make-Trim

The following innovation areas allow for further process optimisation and elimination of any kind of waste in this supply chain step. Cut, make and trim (CMT) is the process of turning fabric into apparel by cutting the garment from a pattern, sewing it together and finally adding the needed embellishments. The wastage from the cutting itself is normally found in the range of 6 -25 % of the fabric26. The cutting waste can be reduced through minimal seam construction and designing for zero-waste. By optimising the processes and eliminating any kind of waste, the environmental footprint can be reduced.

Retail and Use

While often not at the forefront, the retail and use stage poses challenges that multiply the environmental footprint of the fashion industry. It is estimated that doubling the lifetime of a garment reduces its environmental impact by 49%32, by saving carbon emissions and water that would be used in the production of new garments. Circular business models aim to keep existing garments in use for a longer period while also changing consumer behaviour. Below details the various types of circular business models as well as where they are on the global maturity curve.

End-of-Use

At the End-of-Use the product reaches the end of its lifespan and is no longer in use by its owner. The majority of textiles are not designed for circularity at the end of their use and an overwhelming majority end up in the landfill or incineration. A large percentage of these materials could be reused, recovered and recycled into new materials for the textile industry to use as new feedstock. Today around 25%37 of global garments are collected for reuse and recycling with only 1%38 of the recycled garments converted into new materials.

Overarching Supply Chain

There are quite a few topics that are overarching, with impact across the supply chain. This section covers said topics, looking at traceability and transparency, worker empowerment, supply chain redesign and logistics and packaging. Below is a short overview of opportunities in each of these areas.

Conclusion

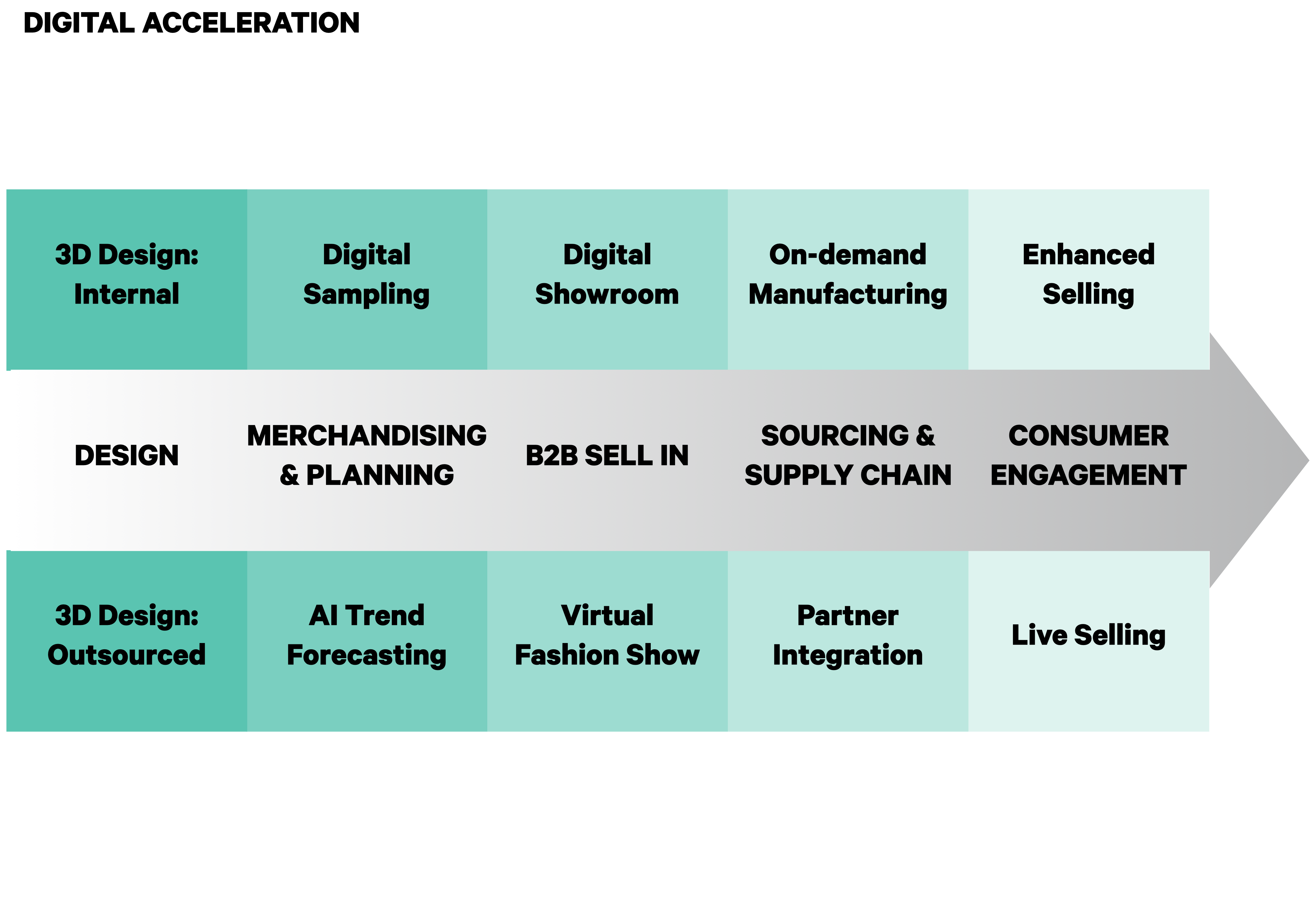

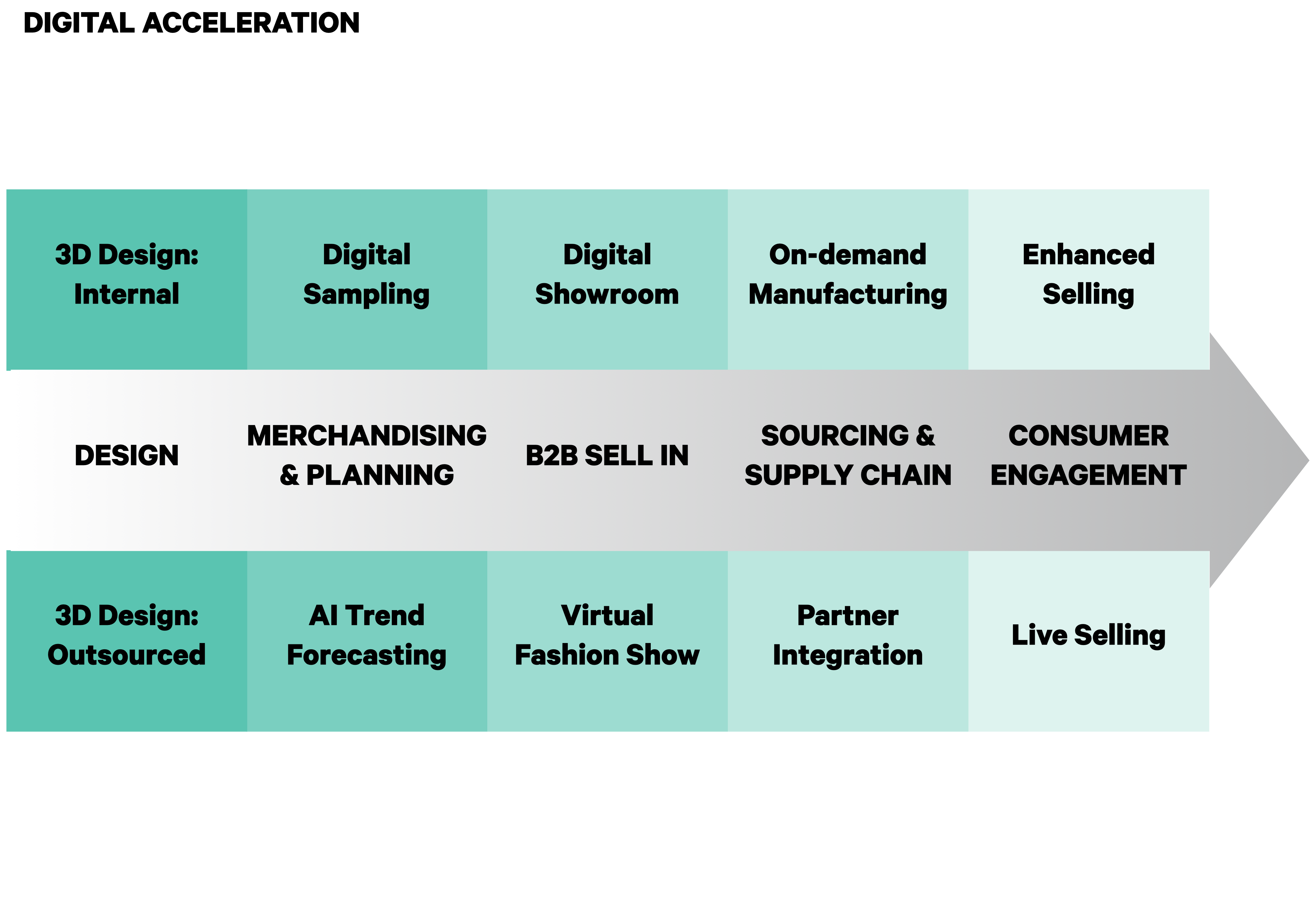

We believe that accelerated dynamism in the circular innovation landscape will drive efficiencies across the Indian fashion and textile supply chain, enabling the industry to leap-frog to sustainability. Innovators developing products, processes and service offerings or combinations thereof at critical points in the supply chain as well as systems level solutions, can usher in necessary disruptions through accelerated adoption and scale.