Textile Processing Guide: Pretreatment, Colouration and Finishing

Disruptive Innovation – Machinery

Disruptive Innovation – Machinery

The key solution to drastically reducing water and energy use in the processing stage of the fashion supply chain lies within moving from wet to mostly dry processes.

In other words, moving away from processing in heated baths and tanks filled with water to machinery that require very little to no water, and therefore significantly less energy and water. An additional benefit to most of these technologies is that little to no wash off is needed.

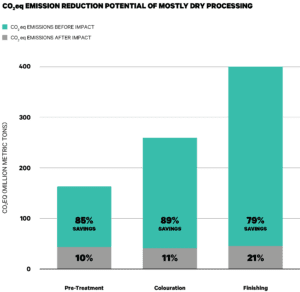

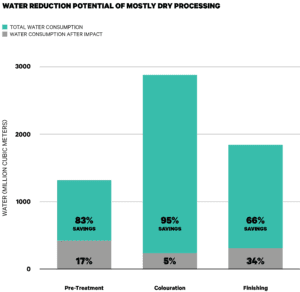

Figure 3 and 4 below, show the potential impact this shift could have. Given wet processes’ significant contribution to total CO2 emissions and water consumption, transitioning to mostly dry processes has the potential to reduce emissions by up to 89%, and to cut water consumption by between 83% and 95%.

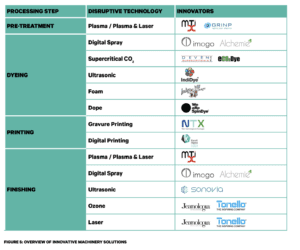

Figure 5 below illustrates some of these disruptive machinery innovations, including some of the innovative companies working in this space.

TECHNOLOGIES AND INNOVATIONS

Plasma / Laser

Plasma, the fourth state of matter, is formed when gas is ionised and becomes more reactive. When this ionised form of gas is applied to a substrate aka surface or fabric, it is able to alter its properties i.e. activating its surface, removing impurities, depositing a coating. It is a waterless technology, has low energy consumption and is effluent free.

MTIX*

MTIX has developed a multiplexed laser surface enhancement (MLSE®) system for textiles. The MLSE® system creates a unique quantum mechanical energy milieu with laser plasma that enables durable technical functionalities, finishes and pre-treatments on all fabric types in a high volume and continuous process.

GRINP*

GRINP develops and produces machines using their proprietary atmospheric plasma technology. Their industrial machines can replace traditional pre-treatments such as bleaching. The technology is fibre agnostic.

Digital Spray Dyeing and Finishing

Nozzles spray the exact amount of dyestuff and finishing chemistry required directly onto the fabric. The process is digitally controlled and therefore highly efficient. As a result, it uses very little water and much less dyestuff and chemistry than traditional processes. This process is not the same as digital printing (explained below), digital printing focuses on creating artworks on the surface of a fabric while spray dyeing mostly focuses on dyeing fabrics in solid colours with deep penetration. As a result, the nozzle openings in digital printers are significantly smaller than those used in spray dyeing. This means that digital printing often needs expensive speciality inks while spray dyeing can work with traditional dyes.

Alchemie*

Alchemie has developed a digitally enabled spray/jetting technology which in combination with their proprietary airflow technology is able to deeply penetrate the fibre. Their dyeing machine is called Endeavour and their finishing machine is called Novara. In addition to these two machines, Alchemie has developed a proprietary fixation process consisting of infrared radiation/heat which fixes the dyes to the fabric. Their high precision means they can dye to shape as well as simple patterns. The technology is compatible with traditional dyes and chemistry and can be used on polyester and cotton fabrics.

imogo*

imogo has developed a digitally enabled spray dyeing and finishing technology, which is used in their Dye-max (dyeing) and F-max (finishing) machines respectively. They use the capillary forces in the materials and the fibre’s natural absorption to get deep penetration. Both machines are compatible with traditional dyes and chemistry and they are currently focusing on cellulosics. Fixation is done by traditional methods such as cold batching.

Supercritical CO2 Dyeing

In conventional dyeing, water is used as a solvent but in supercritical CO2 (scCO2)dyeing, scCO2 replaces water as the solvent. In a supercritical state, CO2 gets the dual advantages of having solubility like a liquid and flow properties like a gas. Due to its gaseous properties the scCO2 can circulate in the dyeing vessel and deposit the dyes onto the textile yarn or fabric. When dyeing is complete, the high pressure vessel containing the scCO2 is depressurised. As a result, the CO2 reverts to its gaseous state and the dye, which cannot stay dissolved in a normal gas, drops to the bottom of the dyeing vessel. Both can be recovered and it is a closed loop waterless dyeing process. As a result, there is no water effluent and the process uses less energy and chemicals.

eCO2Dye*

eCO2Dye has developed a dyeing technology using scCO2. The equipment is designed to dye a variety of yarns and threads on conventional cones or packages using scCO2. Traditional dyes which are compatible with scCO2 have been identified. The process uses existing CO2 which is recycled after each dyeing process cycle. Pre-treatment (e.g scouring) and dye removal from waste textiles with supercritical CO2 is in research and development (R&D). The technology can be used to dye polyester and wool yarns.

Deven Supercriticals*

Deven Supercriticals has developed a dyeing and finishing technology using scCO2. Rather than only introducing the dye in the dyeing vessel, they precoat the fabric with dyes and chemicals before it enters the dyeing vessel, using the scCO2 to improve their solubility in scCO2 with it before it enters the dyeing vessel. This makes their technology compatible with traditional dyes and can be used to dye polyester, cotton and cotton-polyester blends.

DyeCoo has developed a waterless and process chemical-free supercritical CO2 dyeing solution. Their technology uses reclaimed CO2 as the dyeing medium in a closed loop process. The Fabric or yarn is loaded together with pure dye into the dye vessel where the liquid C02 is released. When pressurised, this CO2 becomes supercritical (sc-CO2). Thanks to the high permeability, the dyes are transported easily and deeply into fibres, creating vibrant colours. Their technology is applicable to both synthetic fabrics and yarns with a primary focus on polyester.

Ultrasonic Dyeing and Finishing

Ultrasonic waves are acoustic waves that create thousands of microscopic bubbles in a formulation which, when burst, release large amounts of energy. The pressure from the bursting of these tiny bubbles generates powerful jet-streams that are used to physically inject the fabric with the desired chemistries. This process means less water and chemistry is needed as well as fewer additional chemistries like binders.

Sonovia*

Sonovia has developed a compact ultrasonic finishing machine and process that embeds Sonovia’s customised chemistries for finishing applications directly into the fabric. To date, Sonovia has developed antimicrobial and viral finishes as well as DWR, their technology is fabric agnostic.

Indidye*

Indidye uses sound waves to bind their proprietary natural plant based dyes to cellulosic fibres. The dyes are extracted with a water based extraction process and then applied using the ultrasonic technology.

Foam Dyeing

Large foam bubbles carry dyestuff and when the bubbles burst, the pressure deposits the dye on the fabric/yarn. This results in lower water and chemistry usage and as a result it is a more efficient process than traditional dyeing.

Indigo Mill Designs*

Indigo Mill Designs has invented a novel way of applying indigo to cotton yarns, called IndigoZEROTM. The dye is applied to the fibre using a foam system that minimises the uptake of water.

Dope Dyeing

A method of colouring man made fibres by incorporation of the colourant in the spinning composition before extrusion into filaments or fibres. While this is not a new technology, it has the potential to drastically reduce resource consumption in the colouration process.

We aRe SpinDye*

We aRe SpinDye orchestrates the dope dyeing of polyester yarns for fashion brands. Brands get a quality, compliance & traceability We aRe SpinDye®-certificate for all products they take off. This certificate also states Life Cycle Assessment (LCA)-based impact savings compared with traditional dyeing processes.

Gravure Printing

Gravure is different from other printing processes as it prints from depressed, ink-filled cells that are produced on the surface of a cylinder that is copper plated. The ink in these cells is transferred onto the fabric. The process is digitally controlled to engrave the roller and therefore highly efficient. Traditionally the gravure roller requires a transfer of the artwork onto a paper or film which is then transferred onto the material substrate. It is a mostly waterless process that uses less energy than conventional dyeing.

NTX: Cooltrans*

NTX: Cooltrans provides a digitally enabled gravure printing method for both artworks and block colours. Their technology is faster and more precise than other printing technologies and they use proprietary inks (material restricted substance list (mRSL), ZDHC and RSL compliant) that are manufactured in- house. Alongside this, for solid colour applications, their technology transfers from gravure to the material without paper or film. It can be used on all fibre types except polyolefins.

Digital Printing

Digital textile printing is an inkjet-based printing method which enables printers to print high-quality designs from a digital data file onto different fabrics. The ink is deposited in the form of minuscule droplets by the digitally controlled printing heads. It is a mostly waterless process and reduced energy use as no dye bath is needed.

Kornit

Kornit is an established digital printing technology company. They are classified as an innovator/innovative company as they have developed a single step printing solution which combines fixation, dry softening and full curing. It is fabric agnostic.

Ozone

Ozone, which is an alternative form of oxygen and a strong oxidising agent, can be used to clean / bleach the garment, it’s most effective when used inside a washing machine to prevent the gas escaping and to allow for its correct neutralisation. At the end of the process, any remaining ozone is converted back into oxygen. Ozone pre-treatment and finishing reduces water, chemistry and energy consumption and as a result there is also less effluent. Ozone is often used for finishing jeans and also has enhanced performance benefits such as achieving the right shade of blue faster and with lower costs.

Laser

Laser technology is most commonly used as an alternative to manual scraping in denim production; it can also be used to create vintage effects, whiskers, patterns, patches, and even intentional holes and tears in a (denim) garment. Used in combination with other technologies such as ozone, it can replace traditional processes like sandblasting and bleaching which are hazardous to workers’ health.

Tonello and Jeanologia

Tonello and Jeanologia are both established players selling multiple industrial dyeing and finishing technologies with a strong focus on sustainability and denim. They both have ozone and laser technologies as well as several other more efficient washing and finishing processes that have enhanced performance benefits as well as environmental savings.

(*Fashion for Good Alumni – Fashion for Good have supported over 135 innovators through our projects and programmes. They continue to be a part of our alumni network with Fashion for Good providing continued ongoing support.)

CHALLENGES OF SCALING DISRUPTIVE MACHINERY INNOVATIONS

The impact savings mentioned above raise the question as to why more textile mills have not switched to mostly dry processes yet. Below we will elaborate on the challenges of this transition.

Misaligned Incentives and Unequal Power Relations

Although brands have the greatest incentive and the most pressure to drive towards sustainability, efforts are often limited, and the industry expects the upstream supply chain to account for the costs and risks. This results in a misalignment of incentives for major innovation along the supply chain.

High Initial Investment

Investing in new processing technologies is expensive. Alongside this, the investment often falls to the manufacturers who do not always have committed offtake from brands. Increasingly, brands and manufacturers sign letters of intent (LOI), which include a commitment from the brand that they will purchase a certain number of products made using the new technology. Or recent collaborations include an innovator, manufacturer and brand partners jointly investing in a novel machine through a joint venture (JV) structure. The machine is installed at the manufacturer who is part of the JV.

That said, while initial capex for some technologies are high, payback times can be as short as 1 to 2 years as variable costs, from water, energy, and chemistry, are reduced11.

Performance

As with all new technologies, there are risks around the technology’s ability to meet minimum performance requirements for different applications at scale. In addition, mostly dry technologies can impact the handfeel of materials differently than wet technologies. Therefore it is important that the technologies are optimised to achieve the same handfeel as the industry is accustomed to after wet processing.

Incremental vs. disruptive innovation

Brands/manufacturers might feel they have to choose between investing in either incremental or disruptive technologies. Once they have gone down the route of incremental changes, this may form a barrier to invest money in disruptive technologies. Investments in new innovations have the potential to generate higher savings in environmental impact, however it comes with a greater risk. As a result, the direction taken by the brands/manufacturers depends on their strategic priorities and internal risk appetite.