Sorting for Circularity India: Pre-Consumer Pilot Learnings

Key Pilot Highlights and Success

Sorting for Circularity India: Pre-Consumer Pilot Learnings

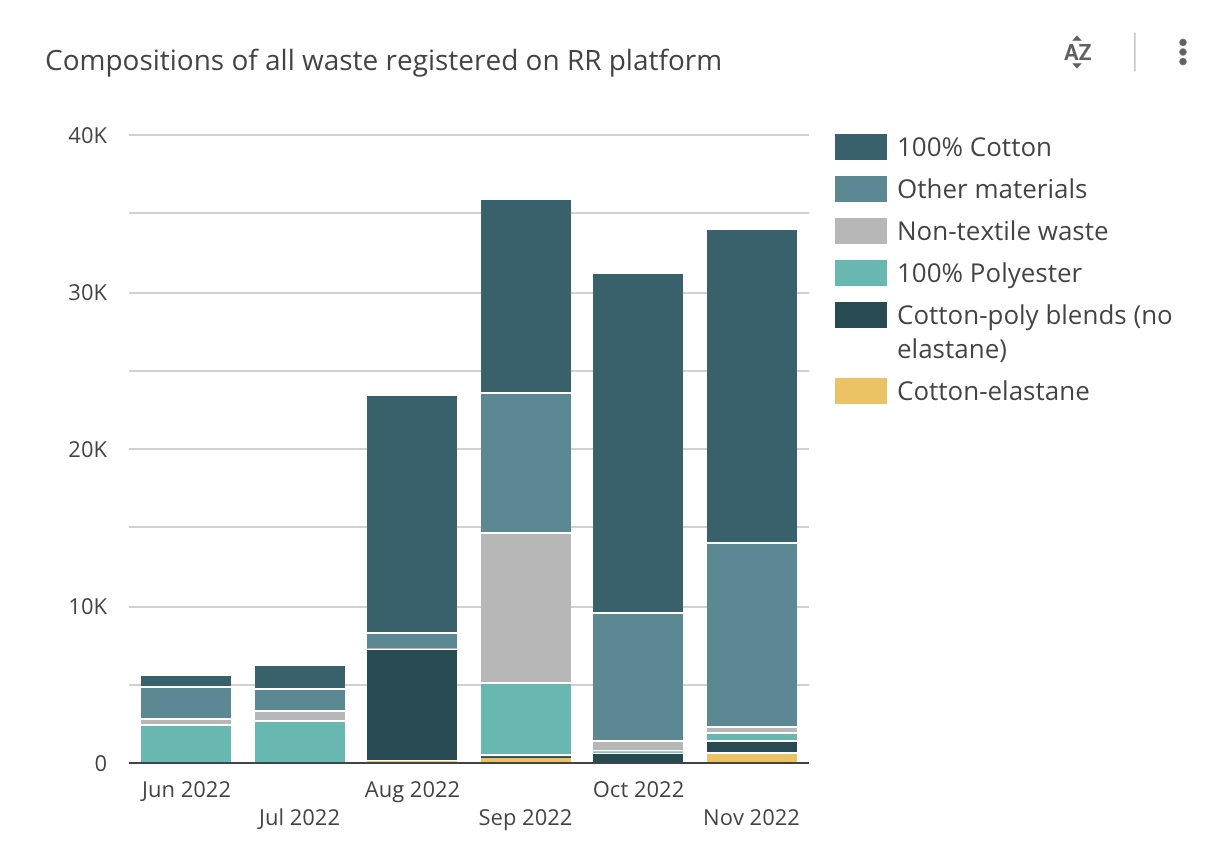

- Segregation training and inventory digitisation activities done by RR brought visibility to the textile waste streams being generated on the factory floor. As shown in Fig4, the pilot activities put a spotlight on the textile waste compositions and their corresponding volumes that were being generated. Eventually by the end of the pilot, ~84 tonnes (and counting) of segregated waste were shipped and digitally traced to recycling and other solution providers in the past four months.

Fig 4: Composition of the waste registered on Reverse Resources platform

- With the segregation, digitisation and matchmaking of waste streams, middle men were minimised and efficiencies were implemented in textile waste supply chains. For instance, refer to Fig 3, Waste flows orchestrated and traced in the pilot, to observe that each shipment does not have more than one waste handler involved. This is a great step away from the typical supply chain that consists of multiple middle men and one that ends up making the recycled outputs expensive. In some cases manufacturers were able to send shipments directly to the recyclers. For instance, SP Apparels and Sri Lakshmi clothing shipped segregated textile waste directly to Usha Yarns and Sri Velayudhaswamy mills, respectively.

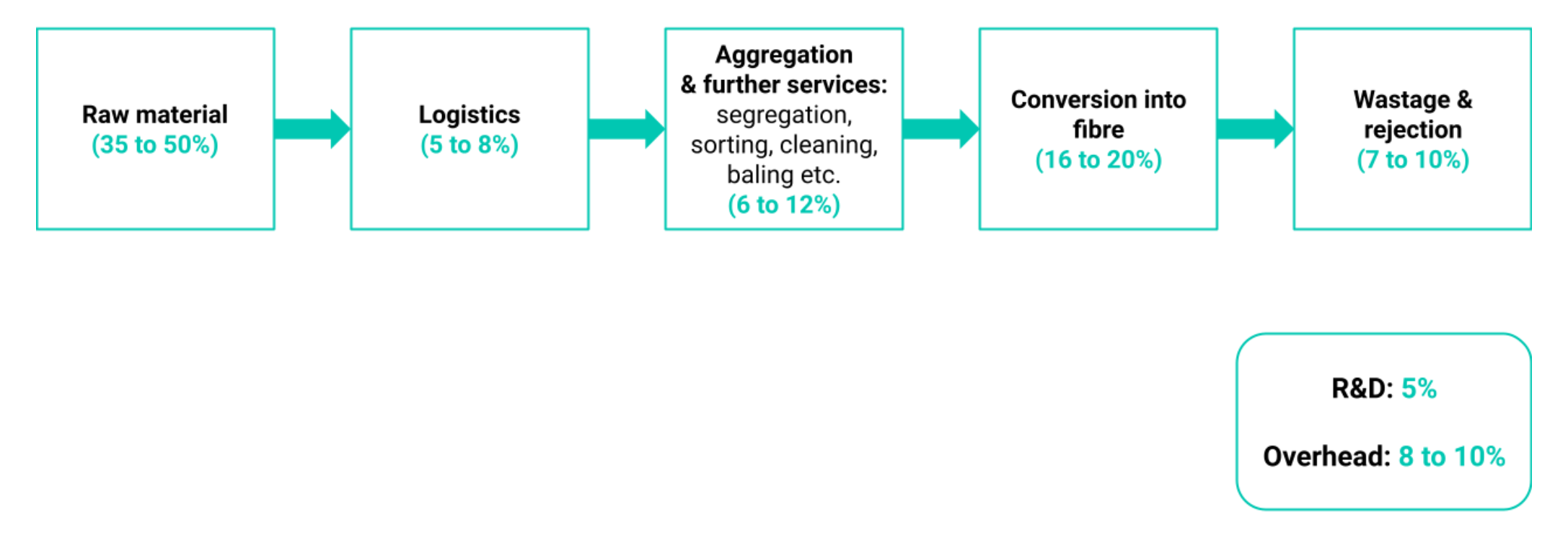

- Cost centres were also highlighted/quantified as part of the pilot; specially for mechanical recyclers given that India has a huge market for mechanical recyclers.

Fig 5: Cost Centres

- Digital trace established and provided evidence for monitoring “Zero Waste to Landfill” targets. For instance, SSR tex, a waste handler, can now exactly trace the textile waste moving from their premises to both textile-to-textile recycling uses and non-textile use cases

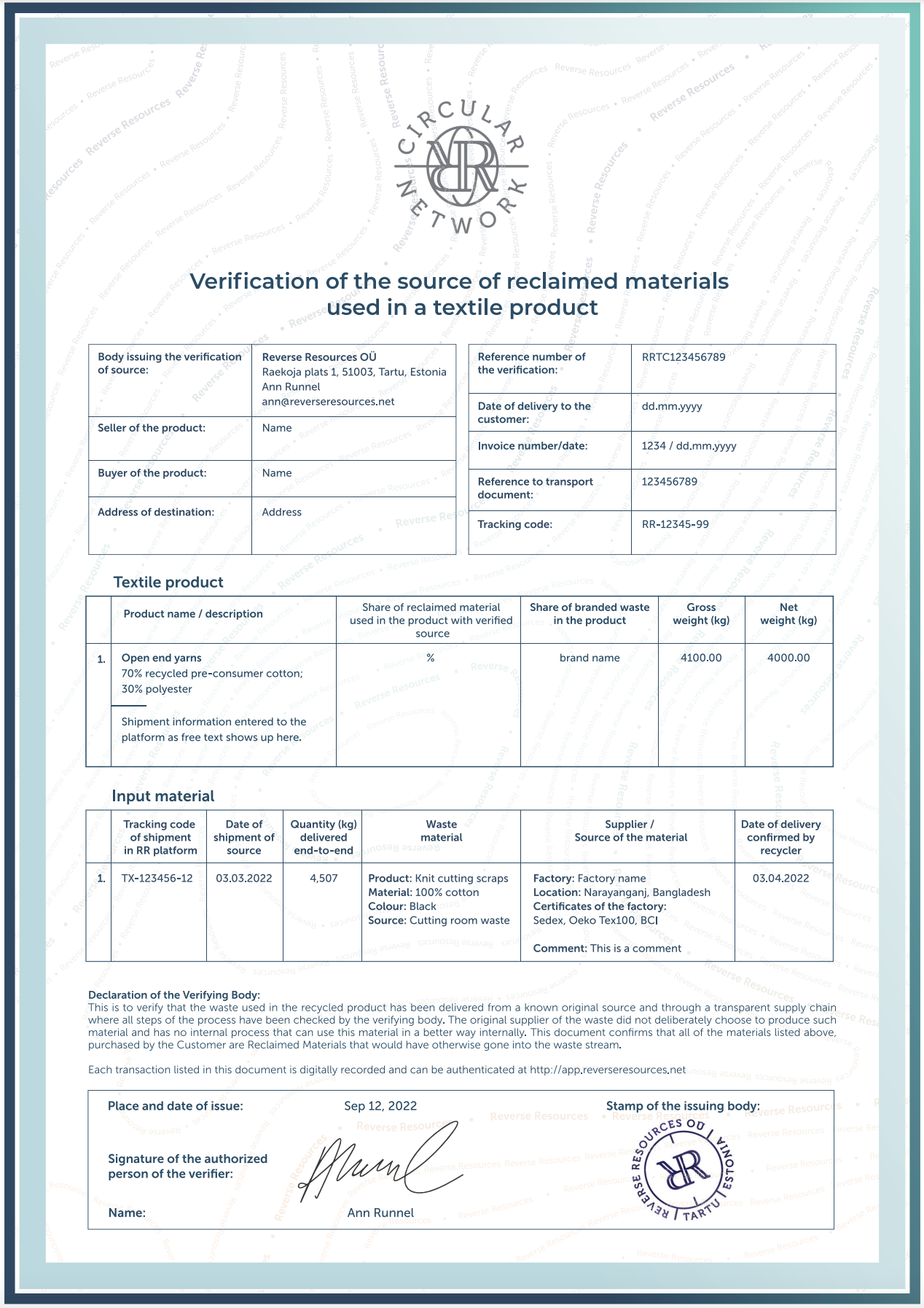

- Recyclers are using the RR platform to access good quality digitally traced waste. For instance, Usha Yarns (high grade mechanical recycler) as a result of the engagement in the pilot has agreed to expand their RR platform usage to begin registering recycled material created against sourced textile waste. This would enable proving how much brand waste went into a specific finished product. A verification document (Fig6) can be secured from RR by recyclers with additional data registration. On the right is an example of a verification document.

Fig 6: Reverse Resources verification document for recyclers

ACCESS TO REVERSE RESOURCES DIGITAL TOOLS AND REPORTS

FOR BRANDS

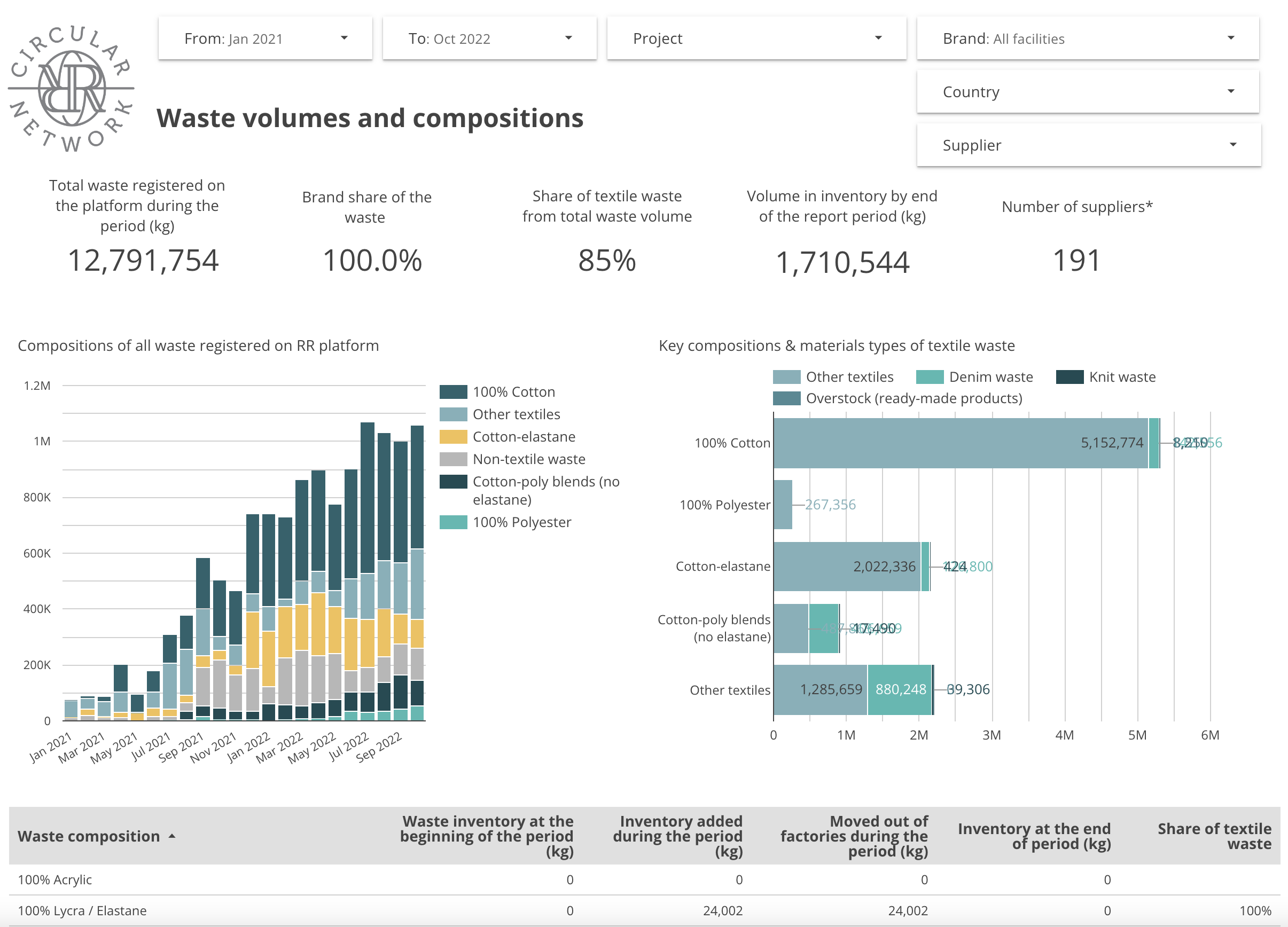

Fig 7: Brand Dashboard live statistics

The brand participants, in the pilot, have been given access to the Brand Dashboard on the RR platform. The brand dashboard provides live data and insights:

- List of their manufacturers on the platform (active vs inactive) who are segregating waste

- Volumes of waste by material type, composition and colour

- Overview of the disposal methods of waste by the manufacturers

- Volumes and types of waste received by brand nominated recyclers

- Coming soon: overview of volume of recycled products made of the waste

Note that Fig8 is an example of the dashboard and the functionality of the Brand dashboard is expected to evolve more in the future. Within this dashboard, brands can also access a LIVE statistics report that provides an overview of all the data from the platform with regards to composition, volumes and types of waste traced in easy to read charts and graphs.

FOR MANUFACTURERS

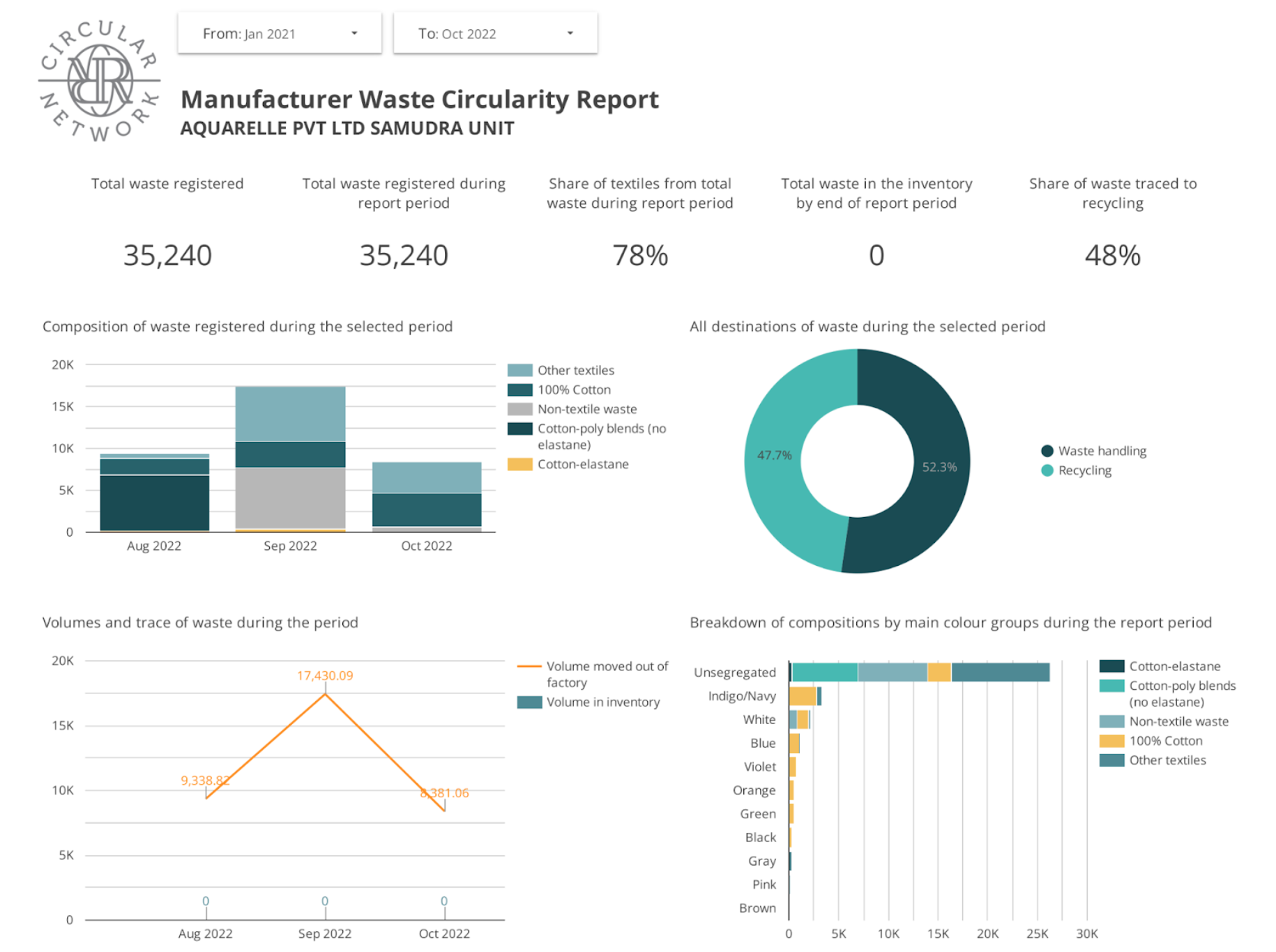

A manufacturer waste circularity report is provided to the manufacturing participants which gives an overview of total volumes, types, composition and colours of waste registered on the platform with a share of textile waste that is sent to recyclers/waste handlers. Fig8 is a snapshot of the report.

Fig8 : Waste circularity report for manufacturers and its waste volumes and compositions

❝Sorting for Circularity programme is definitely a good initiative and need of the future. Looks interesting and I hope this will be a requirement from brands in the near future. The only challenge is that the price offered by approved recyclers is not encouraging. This leads to less interest as a manufacturer.❞

– SP Apparels (manufacturer)