Wealth in Waste: India’s Potential to Bring Textile Waste Back Into The Supply Chain

Perceived Hierarchy Of Textile Waste In India

Presents the first of its kind waste value hierarchy for Indian ecosystem

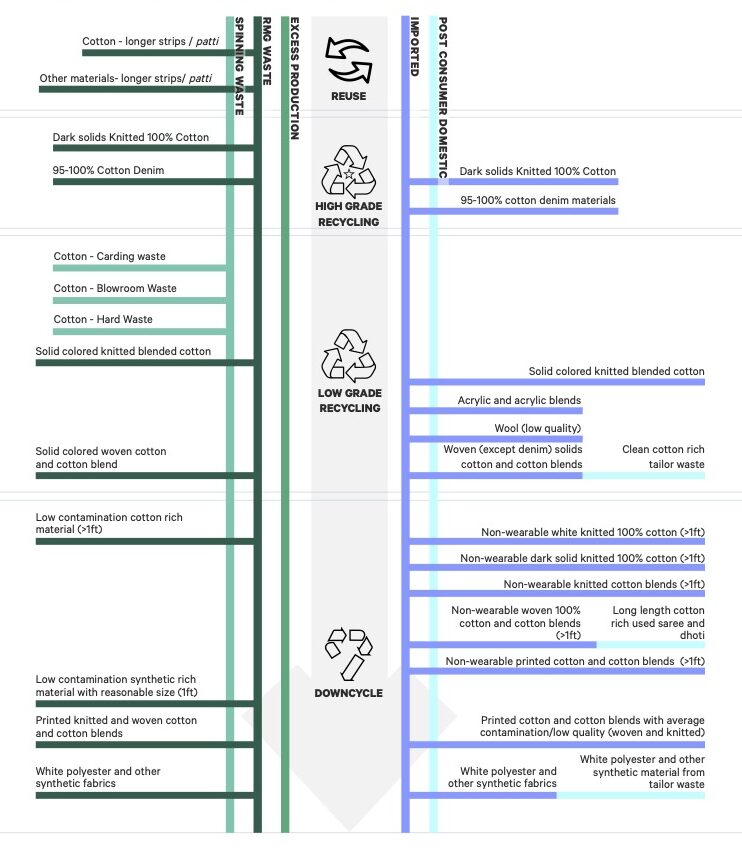

PERCEIVED HIERARCHY OF TEXTILE WASTE BASED ON TYPES, SIZE, COLOUR, MATERIAL COMPOSITION AND CONDITION

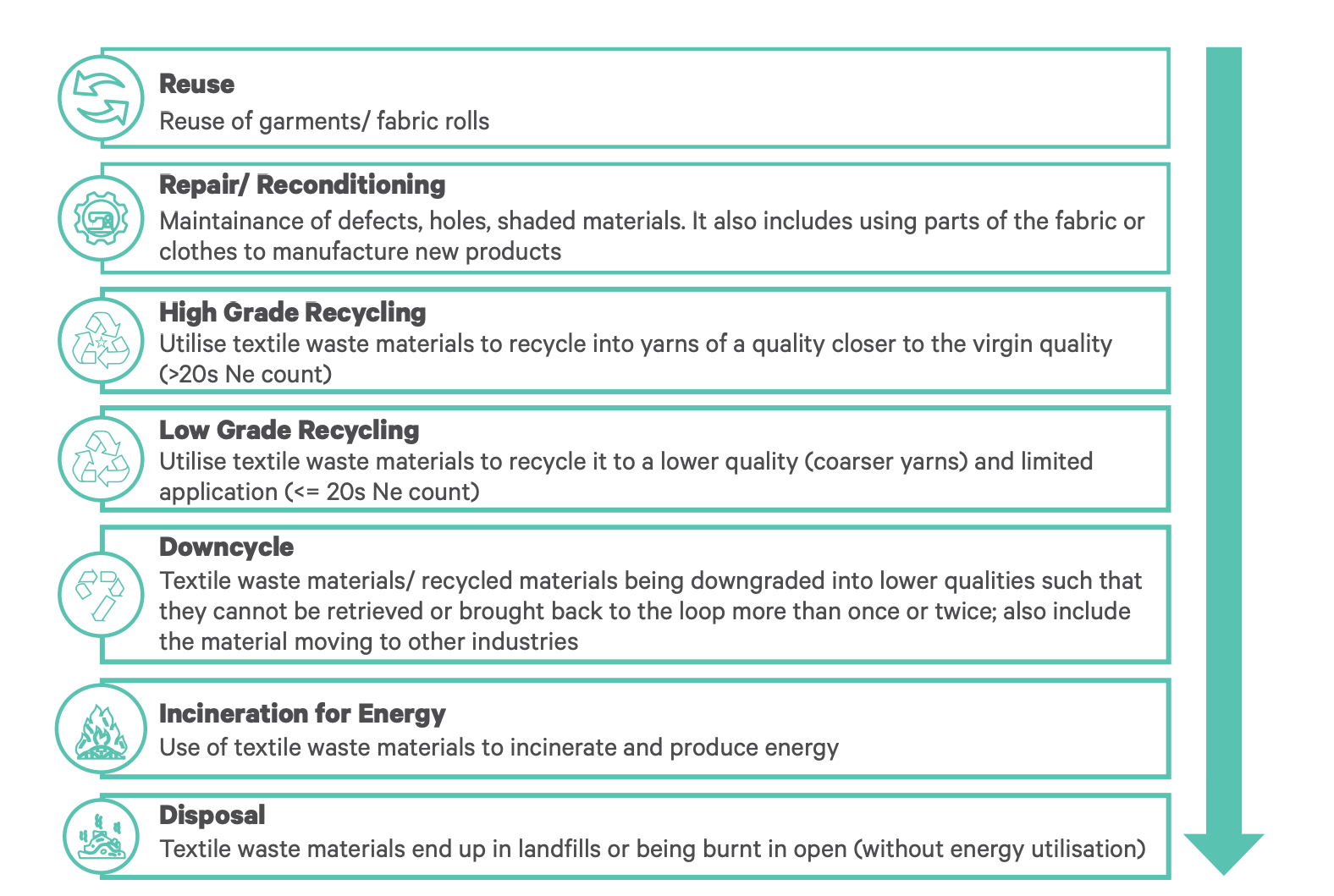

Using the EU waste hierarchy framework, this study has developed a first-of-its-kind textile waste value hierarchy for India that provides a consolidated view of how the ecosystem currently perceives the value of the different waste types.

The hierarchy presents the current value of waste and identifies waste types to further valorise. However, the value of waste is dependent on its type, purity of feedstock, technologies that can revalorise it and demand for its recycled form. This hierarchy, though not exhaustive, acts as a toolkit for the ecosystem to understand waste types that require interventions to realise their full value potential.

The study has contextualised the European Environmental Agency’s60 end-use hierarchy framework Reuse energy utilisation) to understand the valorisation and flow of textile waste in India.

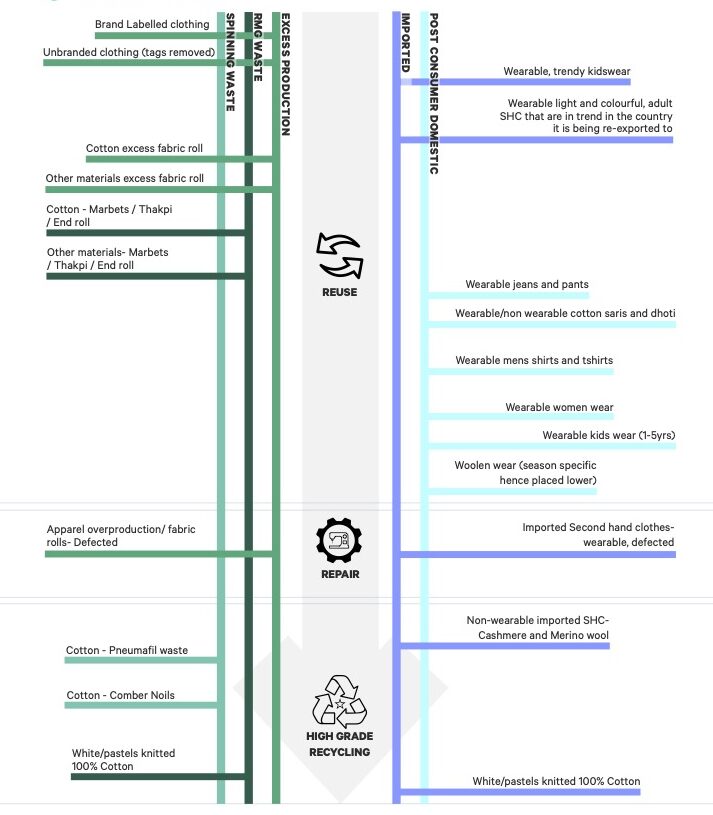

Illustration 29: Factors determining end use of imported waste

Developing the textile waste hierarchy framework:

One waste type can have multiple use cases and therefore the developed framework takes into account various parameters such as contamination, fabric construction, colours and prints, to define the accurate position of the waste type. Despite this, not all use cases of a waste type have been captured in this simplified version and our understanding of the ecosystem suggests that every material in the hierarchy can be used for a lower level application depending on market demand and conditions. Additionally, the cost of waste has not been used as a parameter to determine the value of waste since it was found to be varying in different locations and levels of the value chain. Moreover, the cost of textile waste was found to be significantly dependent on the prices of virgin material and hence, subject to high market volatility.

While textile and non-textile industries in India have been able to find use cases for most waste types, over 50% of total waste is not being realised to the highest value. In addition, the industry also values the same fabric composition from different waste streams differently. For example, a 100% white cotton fabric from a pre-consumer waste stream is considered more valuable than the same material from imported and domestic post-consumer waste streams. This difference emerges due to the different levels of contaminations across waste streams, pre-processing requirements and availability. The hierarchy is split between material types within each waste stream with high and low value realisation. The study further explored the opportunities and interventions that can help move low value materials to high value.

High Value Realisation

Illustration 30: Waste types which have a high value realisation

Less than 50% of the textile waste in India is being reused, repaired or undergoing high grade recycling. These materials include fabric deadstock, re-wearable clothing, apparel overproduction and white-knitted 100% cotton waste.

Adequate technologies and focus exists to realise the potential of these materials. However, the unorganised nature of the industry and limited traceability makes access to these waste types difficult. Moreover, new age recycling technologies and standards around segregation could further improve the potential of value realisation here.

Low Value Realisation With Significant Volumes

Illustration 31: Waste types which have a low value realisation and are present in significant volumes

Solid coloured cotton, MMCF blends and printed textiles form a significant volume of total waste generated in India and require a high industry focus to prevent value loss as the current recycling technologies are limited in their capabilities to process them.

The downcycled use cases for these materials renders it unfit for bringing it back into the textile industry. These waste types require extensive innovations and infrastructure development for segregation and recycling. Furthermore, it requires awareness building and incentivisation in the waste value chain to realise the need of sorting these materials efficiently and improving their recyclability. Even though there are advanced recycling technologies available for cotton and cotton blends, they are currently not scaled. Hence, most of these materials go through a low grade recycling or downcycling in India, which limits the reusability or recyclability of the material in the next cycle.

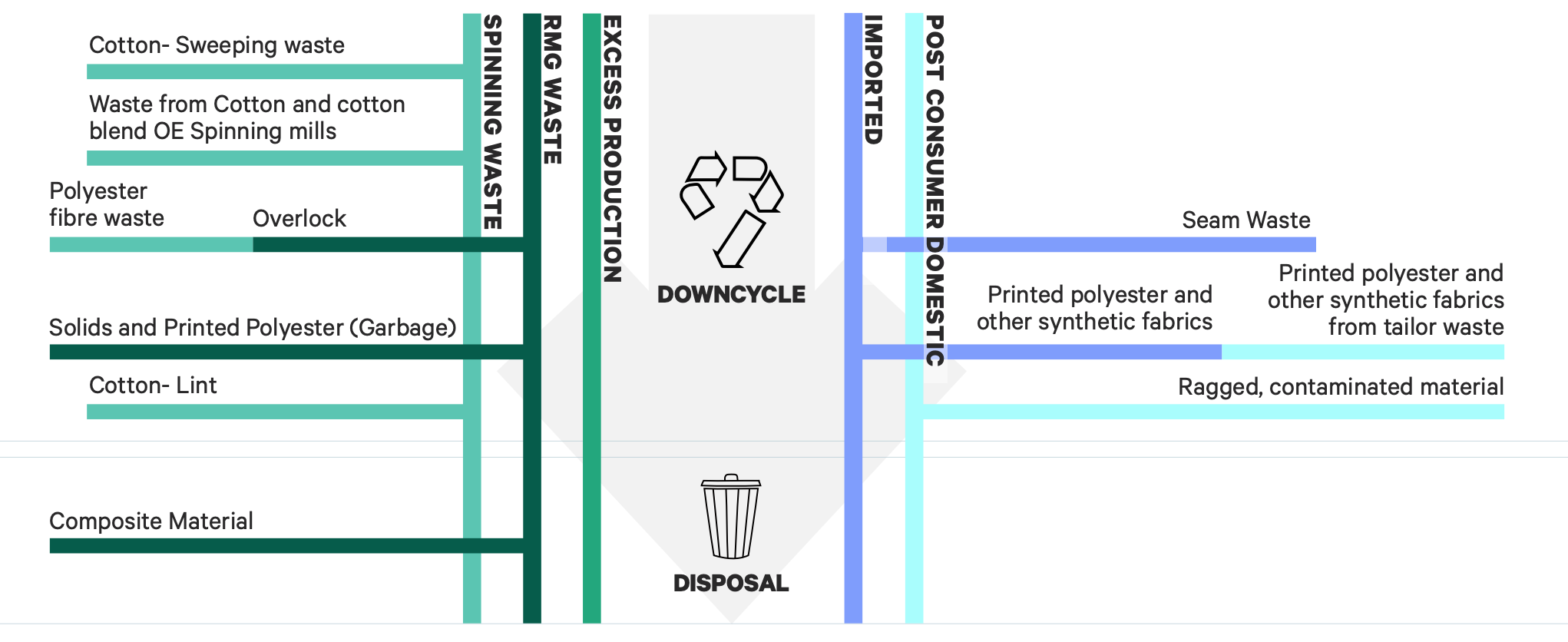

Low Value Realisation With Low Volumes

Illustration 32: Waste types which have a low value realisation and are present in small volumes

Certain spinning waste types and materials like printed synthetics have very little value being retrieved from their usage, however they hold a high potential.

Sweeping waste from the cotton spinning process and polyester fibre waste still retain the virgin quality of the material and can be brought back to the textile industry. Similarly, printed polyester materials are resource intensive during the manufacturing process, and quality of polyester varies extensively. A lot of these low quality synthetics have no solutions yet. Polyester waste types can be supported by decolouration and chemical recycling technologies focused on synthetics, but only once these technologies scale.

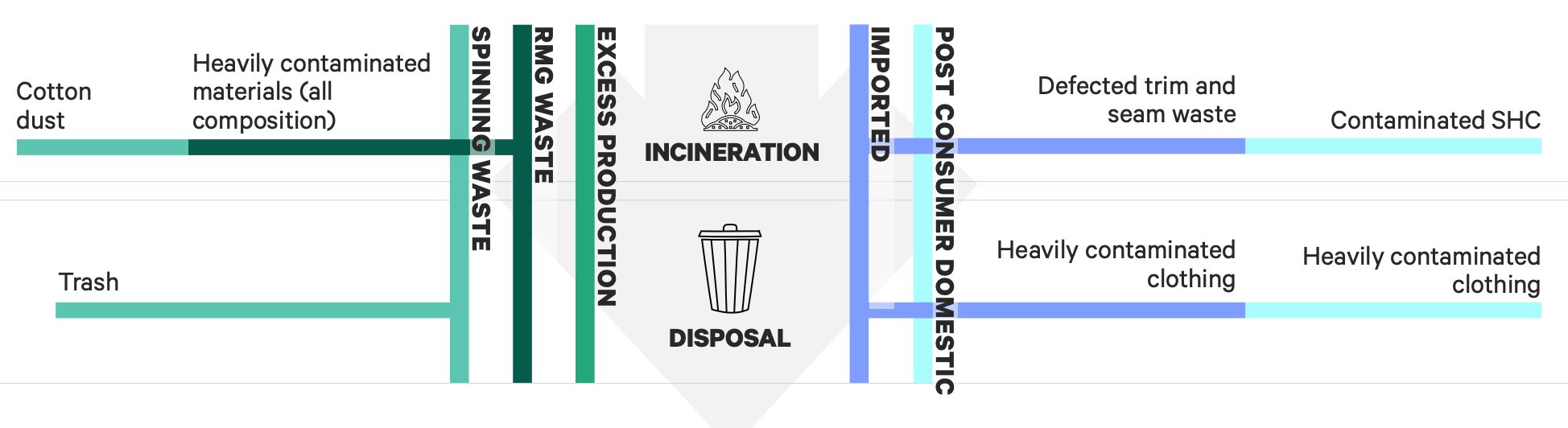

Low Value Potential

Heavily contaminated and ragged materials which have reached the end of their life are difficult to retrieve as they end up being incinerated/ landfilled.

Even from a circularity perspective, one can work to reduce generation of waste at consumers’ end and manufacturer’s end to reduce waste going to landfills, or identify use cases to retrieve them back into textile value chains.

MOVING WASTE UP THE HIERARCHY – ANTICIPATING THE UPCOMING DEMAND OF RECYCLING TECHNOLOGIES

Why is it important to bring waste up to high realisation?

- Industry Momentum and building pressure: With the global textile industry moving towards decarbonisation, there is momentum in the industry to reach net-zero within the next three decades. To reach net-zero, however, the industry needs to reduce the use of virgin materials and avoid any waste leakages. The waste types that have potential in the textile industry must be circulated through reuse and later recycled. With the pressure on industry emissions building in western governments, coupled with brands making commitments to long term sustainability, India, as a primary sourcing region, is starting to feel the global momentum through the sourcing brands.

- Advanced Recycling Technologies at the cusp of implementation need higher quality feedstock: Most chemical recycling technologies that are able to recycle cotton or polyester or separate blends are in the nascent stage of development. As they develop large scale capacity, they will require large volumes and very high quality textile waste as feedstock. According to a recent report by Mckinsey, fibre-to-fibre recycling in Europe alone can increase to 26 million tons by 2030.61 This exponential growth in the global recycling industry would put pressure on the various production markets for textile waste feedstock as well as markets with high post-consumer waste. Mechanical recycling, on the other hand, has also seen an uptake in demand due to technology upgradation, increasing the need for traceable high quality feedstock. India already has large volumes of cotton, cotton rich (~4700 ktons) and polyester waste (~1400 ktons) that can be fed into the recycling technologies.

- Demand for traceability as an enabler to scale: Industry’s momentum to reach net-zero requires visibility of the supply chain and traceability of materials and their composition. Moreover, the exponential growth of recycling technology will require uncontaminated waste and a system to acquire traceable waste. Building resilience in these systems, coupled with transparency will be required for a smoother transition.

How can we move waste up the hierarchy?

- Generating less or better quality waste: There’s a need to anticipate potential waste at the design stage and design accordingly to minimise or make it reusable. This could be done by revamping the production process to reduce waste, but also perceive waste as a resource at production. In the case of domestic post-consumer, there’s a need to recover waste directly from consumers rather than recover soiled waste from landfills

- Investments into sorting and segregation technologies: Efficient sorting and segregation can make low-value waste into high-value feedstock for recycling technologies by removing contamination and disruptors while validating the material composition.

- Systems, infrastructure and regulations for waste: Organising the unorganised market, incentivising visibility and access to waste will help retail high-value waste for high-value recycling. This will also help in retaining the fibre integrity, which may result in better materials that can be rotated in the supply chain.

- Upgrade mechanical recycling facilities and enable chemical recycling: A large segment of mechanical recyclers currently reduce the fibre length, strength and quality. Upgrading mechanical recycling can lead to higher quality fibres from waste. Additionally, investment in chemical recycling could open doors to large-scale processing of virgin grade materials.

- Engaging business models, so that price is not a barrier for materials to circulate in a continuous loop: The price of textile waste is a significant barrier, and with additional services of sorting and segregation, the price can be unsustainable for building sustainable business models.

The next section, Part 5 of the report details out the key levers that will help move the waste up the hierarchy and resolve the anticipated challenges in the textile waste ecosystem.