The Textile Tracer Assessment

Executive Summary

Fashion for Good, together with Textile Exchange, have created a detailed analysis for benchmarking physical tracer technologies relevant in the textile industry.

This report is the first step to creating an open-source guide where all interested parties can identify which tracer technologies are best suited for their traceability motivations, use cases, and scope. This includes understanding which tracers work well with which fibres, materials, and the challenges involved. This guide aims to accelerate the development and scaling of tracer technologies in the textile supply chain.

For the tracer technologies themselves, this enables a platform for exposure to suppliers, manufacturers, brands, retailers, sustainability programmes, and certification bodies to help drive further growth and implementation.

The assessment of tracer technologies will further support chain of custody scheme owners to explore aligning physical/material-level verification to the existing site-level and transaction-level verification. The Textile Tracer Assessment could contribute to wider supply chain risk assessment and management, as well as more strategic and streamlined auditing processes.

KEY TAKEAWAYS

An analysis of 17 tracer companies led to the following key takeaways:

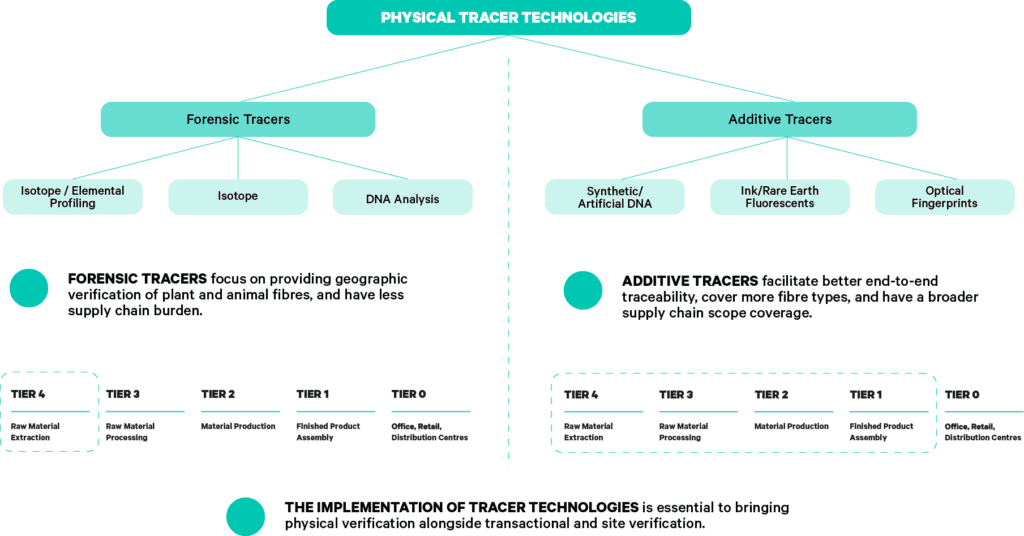

Based on the innovations and scientific methodologies used, there are two main categories of physical technologies:

- Forensic tracers

- Additive tracers

Forensic tracers focus on providing geographic verification of plant and animal fibres and have less supply chain burden.

Forensic tracers mainly focus on verifying the geographic origin of natural fibres, and have less supply chain burden for the user compared to their additive tracer counterparts.

Additive tracers facilitate better end-to-end traceability and have a broader use case in terms of meeting the users traceability objectives

Additive tracers have more supply chain burden, but more versatility for the user. They cover more fibre types, and have a broader supply chain scope coverage (e.g. can work more proficiently with synthetic fibres and the middle tiers of the supply chain than their forensic tracer counterparts).

The implementation of tracer technologies is essential to bringing physical verification alongside transactional and site verification13

Tracer technologies are the catalyst to strengthen chain of custody models within sustainability standards, providing physical evidence of geographic and supply chain origin to supplement transactional and site verification.

Tracer technologies: one piece of a bigger puzzle

Tracer technologies are used to verify origin, create traceability of information, and flag problems in the supply chain. They do not effectively remediate environmental or social concerns, and therefore should be considered as one part within a larger sustainability strategy for the user.

Great opportunities lie ahead

Looking forward, there are various exciting opportunities to pursue increased physical traceability in the textile industry:

- Implementing tracer technologies in the post-gate circular economy to verify mechanically and chemically recycled fibres

- Scaling the use of tracer technologies to verify sustainable product claims and sustainable fibre content

- Opportunities for further pilots and partnerships between tracer technologies and suppliers, manufacturers, brands, and retailers, to further strengthen the integrity of sustainably sourced fibres and materials

FIGURE 1: Key takeaways of the Textile Tracer Assessment

CALL TO ACTION

Use the Textile Tracer Assessment to accelerate the implementation of tracer technologies

Industry players should utilise the Textile Tracer Assessment to select appropriate tracer technologies for their needs, facilitating the scaling of traceability innovation in the textile industry.

Other Tracer Technologies, come forth!

This is just the beginning. Fashion for Good and Textile Exchange are calling all tracer technologies applicable to the textile industry to come and be a part of the Textile Tracer Assessment so that new technologies and capabilities can be showcased to the industry.

Physical traceability shouldn’t be pursued in isolation

Implementing physical traceability solutions (tracer technologies) should be done in tandem with digital traceability. Alongside the push to digitise chain of custody documentation and supply chain information for suppliers, brands, and retailers alike. Digital traceability and physical traceability need to be performed in parallel to provide the user with holistic traceability validation.

In addition, for sustainability standards and certification bodies, physical/material verification (provided by tracer technologies for fibres and materials) should be seen to supplement existing transactional and site verification mechanisms, not replace them.