The Textile Tracer Assessment

Introduction

The Textile Tracer Assessment is a comprehensive overview and user guide designed to accelerate the understanding and implementation of tracer technologies across the fashion and textile supply chain.

The intended target audience is various fashion ecosystem stakeholders e.g. suppliers, manufacturers, brands, retailers, sustainability programmes, scheme owners and certification bodies that hold motivations to explore technologies to supplement existing fibre traceability in the textile supply chain. The tracer technologies themselves are segmented into two main categories: forensic tracers and additive tracers. The research study interviewed 17 tracer companies via questionnaires and fill out spreadsheets, obtaining claims on which fibres the tracers are effective on, which supply chain scopes the tracers are effective within, application and detection processes, amongst many other enquiry topics. The use case of this report falls into the broader business relevance of traceability in the textile industry.

WHY USE THIS REPORT

INDUSTRY CHALLENGES FOR TRACEABILITY

In the fashion and textile industry, there is a lack of reliable physical traceability for fibres, materials, and finished products. Robust physical traceability and verification requires validation at site-level, transaction-level and material-level to ensure suppliers conform to specific operational and sustainability criteria, validating that the materials exchanged along the supply chain reconcile correctly with inventory, and that fibres can be authenticated in the product.

Current chain-of-custody documentation and auditing processes address site-level and transaction-level assurance, but fall short in physical/material authentications which may lead to false claims and the sourcing of fibres and materials with unchecked environmental risk.

The need for robust traceability and verification is further influenced by:

- Incoming corporate due diligence legislation

- Brands’ commitment to international science-based climate targets

- Consumers’ growing demand for better transparency and traceability understanding, to know who made the products they buy, and from where they were sourced

Tracer technologies (categorised in this report as forensic and additive tracers) that supplement existing site-level and transaction-level verification, have the capability to provide physical/material validation in addition to chain of custody, to allow for:

- Manufacturers, brands, and retailers to more confidently verify sustainable product claims of the physical material

- More targeted audit planning and sampling by supplementing existing site-level and transaction-level verification with additional physical and material risk assessments made available through tracer technologies

- The incentivisation of suppliers and manufacturers to meet the criteria of sustainability standards and certification, ironing out upstream supply chain certificate counterfeiting and deterring material substitution

- Verified environmental, social, and human sustainability data through an additional verification layer of physical traceability for fibres and materials

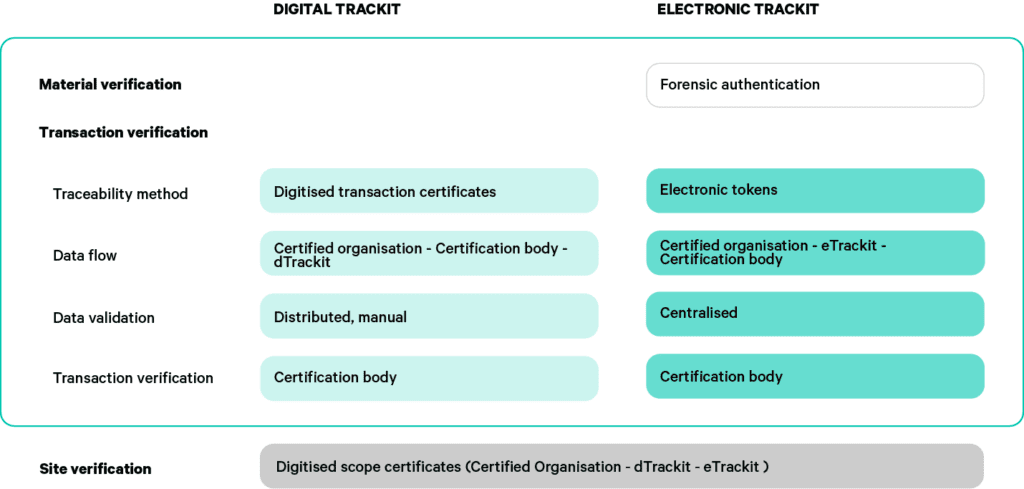

Current methods of commodity and informational exchange in the textile supply chain (e.g. manual and/or digital chain-of-custody documentation) can benefit from science-based physical and forensic verification of the fibres and materials present in a final product. Tracer technologies can add this important additional layer of traceability authentication on top of site and transaction verification. Each pillar of verification plays a different but integral role in overall product verification and traceability. See below in Figure 2, to see how physical/material verification can supplement existing site and transaction verification for Textile Exchange’s Digital and Electronic Trackit programs.

TRACKITTM PROGRAM – TRACEABILITY PATHWAYS

FIGURE 2: Textile Exchange’s Digital and Electronic Trackit verification and chain of custody mechanisms

LANDSCAPE OF TRACEABILITY SOLUTIONS

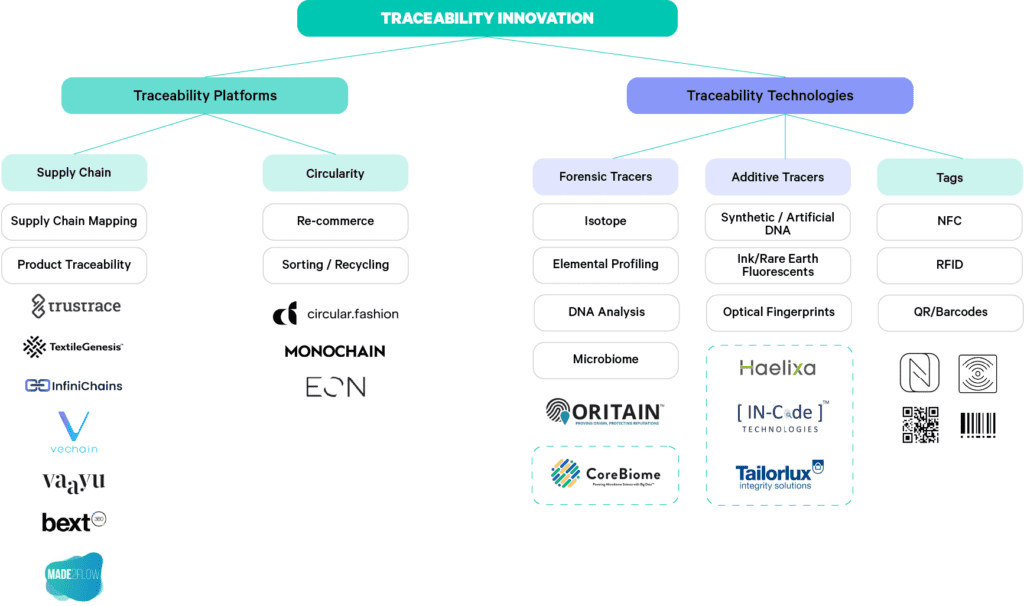

Through desktop research, innovator outreach and existing knowledge at Fashion for Good and Textile Exchange, this report has segmented the traceability landscape in the fashion and textile industry into two overarching groups (see Figure 3 below):

Tracer Technologies *focus of this report

- Forensic tracers* (5 companies assessed)

- Additive tracers* (12 companies assessed)

- Tags

(Digital) Traceability Platforms

- Supply chain

- Circularity

FIGURE 3: Traceability innovation landscape: categories and some example innovators (not exhaustive)

FORENSIC TRACERS

Forensic tracers are innovations that analyse the biochemical composition of fibres, materials and/or garments through micro-particle analysis of isotopic ratios, DNA structures, and elemental meddles. The micro-particle analysis is used to validate the geographic origins via scientific methodologies. The methodologies aim to cross-reference the biochemical composition of samples pulled from the supply chain against predetermined and verified provenance databases to ensure traceability validation.

Application processes for forensic tracers are non-existent, due to the fact that detection processes consist of analysing naturally obtained elements from the environment, rather than detecting substances added by human intervention (as is the case with additive tracers – see below). Furthermore the detection processes usually occur off-site and away from the operations of the supply chain.

There are three sub-categories within the forensic tracer category:

- Isotope/elemental Profiling

- Isotope (only)

- DNA analysis

ADDITIVE TRACERS

Additive tracers are innovations that apply a tracer substance to fibres, materials, and/or garments on the supply chain floor, and then detect that same substance later down the supply chain to validate origin. Examples of application mechanisms range from spraying mists, applying liquid-inks and pigments, printing nano-invisible inks, and printing digital serialisation markings onto product labels and fabric rolls.

Examples of detection mechanisms range from handheld and in-line UV light detectors, portable test kits, and smartphone/tablet photographic scanning (non-exhaustive).

There are three sub-categories within the additive tracer category:

- Synthetic/artificial DNA: Use of DNA codes and molecular identifiers that can be applied to fibre or materials

- Optical fingerprints: Digital watermarks and nano-invisible prints applied to fabric rolls and garment labels

- Ink/rare earth fluorescent: Safe, UV and IR legible fibre and material markings (invisible luminescent pigment inks or rare earth materials)

THE TRACER COMPANIES ASSESSED:

FIGURE 4: Categories of tracer companies included in the Textile Tracer Assessment

HOW TO USE THIS REPORT

WHO IS THIS REPORT FOR?

The Textile Tracer Assessment is for any fashion and textile industry players who wish to pursue fibre and/or material verification in their supply chain and increase traceability integrity of their sourcing landscape. This report benchmarks the key tracer technologies that can provide physical verification effectively, to allow users to align the correct technologies with their objections for traceability.

The report and its findings are intended to be used by a wide variety of stakeholders as mentioned below, all of which may have different supply chain criteria to verify by using such tracer technologies:

- Suppliers

- Manufacturers

- Brands

- Retailers

- Sustainability programmes

- Certification bodies

ASSESS TRACEABILITY OBJECTIVES, THEN SELECT APPROPRIATE TRACER TECHNOLOGY

The Textile Tracer Assessment is most pragmatically useful if the users have already determined their motivations for traceability, and have concretely understood which fibres, materials, areas of their supply chain, and associated economic, environmental, and social criteria they wish to map, improve, communicate, and verify. The users of the tracer technologies have to understand the landscape of their supply chain data integrity issues, and pursue data governance and stakeholder engagement in order to create an environment fit for tracer technology implementation.

Key considerations:

Which fibres and/or materials are you focusing on?

Which part of the supply chain do you want to bring provenance and traceability verification to?

- Read “Part 1: Fibre or Material Use Cases” and View Figure 5 to better understand the tracer technology categories and which tracers work well with the fibre types you wish to trace

- View Figure 6/7 to understand which tracers work well with your supply chain scopes

-

- Read “Part 2: Supply Chain Coverage: Application” for analysis of the application processes and capabilities of the additive tracers

- Read “Part 3: Supply Chain Coverage: Detection” for analysis of the detection processes and capabilities of both forensic tracers and additive tracers

- View Figure 8 to understand which tracers can detect the mixing and blending of fibre types effectively

- Read the descriptions of the tracer companies themselves in the about the Tracer Companies

Forensic and additive tracers are a piece of a larger puzzle of data validation, traceability, and governance that enables industry players to meet operational and sustainability targets. The effectiveness of tracer technologies are subject to how well they are integrated within broader supply chain mapping and traceability digitalisation efforts. From a Fashion for Good perspective, physical verification enabled by the implementation and performance of (additive or forensic) tracer technologies on fibres and materials, should be pursued in tandem with digital traceability and not in silo:

Digital traceability includes (non-exhaustive):

- Supply chain mapping: perform site-level verification, creating visibility and engagement with your supply chain landscape and facilities

- Product traceability: perform transactional-level verification via tracking product journeys either by fibre forward or garment backward approaches

STRUCTURE OF THE ANALYSIS

The Textile Tracer Assessment report consists of four key parts:

- A landscape of tracer technologies in the textile industry (see page 16)

- Results of the study: an analysis of the performance of the tracer technologies in three areas (see below for further detail):

- Fibre and material use cases

- Application processes of the tracer technologies within the supply chain

- Detection processes of the tracer technologies within the supply chain

- A conclusion with key statements regarding the tracer’s capabilities

- An appendix which provides additional information to each section of analysis (how to read figure tables)

RESULTS OF THE STUDY

Part 1: fibre and material use cases

Part 1 analyses the claims made by both the forensic and additive tracer companies on the capabilities of tracing different fibre and material types in the fashion and textile supply chain. (See Figure 5).

Part 2: supply chain coverage: application

Part 2 analyses the claims made on the application processes of the tracer technologies within the fashion supply chain, focusing on one main element and various sub-elements.

Part 3: Supply Chain Coverage: Detection

Part 3 analyses the claims made on the detection processes of the tracer technologies within the fashion supply chain, focusing on two main elements and various sub-elements.

DISCLAIMERS

Comment and analysis are built on claims and information provided by the tracer companies

It should be noted that the analysis of this report is based on information directly provided by and verified with the tracer companies. Fashion for Good did not proof-test the operational performance, efficacy, and associated claims of the tracers. This was strictly a desktop landscape analysis. Therefore qualitative and qualitative analysis, aggregations, graphs and tables of this report have relied on truthful responses by the representatives of the tracer companies themselves, and are subject to continual change, updates, and modification.

Report focuses on technical and operational capabilities and performance of tracer technologies, not defining traceability strategy for the user

The scope of research and analysis for the Textile Tracer Assessment focuses primarily on the technical and operational feasibility of the tracer technologies. Analysis surrounding the traceability objectives that would support the implementation of the tracers, and relevant economic, environmental, and social data points pulled from the value chain, was not the focus of this report. This alternative enquiry would be best realised with a different focus and set of interview questions: varying the interviewee list (to brands, retailers, and civil-society/public institutions) and a heightened focus on the reasons behind implementing traceability solutions.