The Textile Tracer Assessment

Part 1: Fibre and Material Use Cases

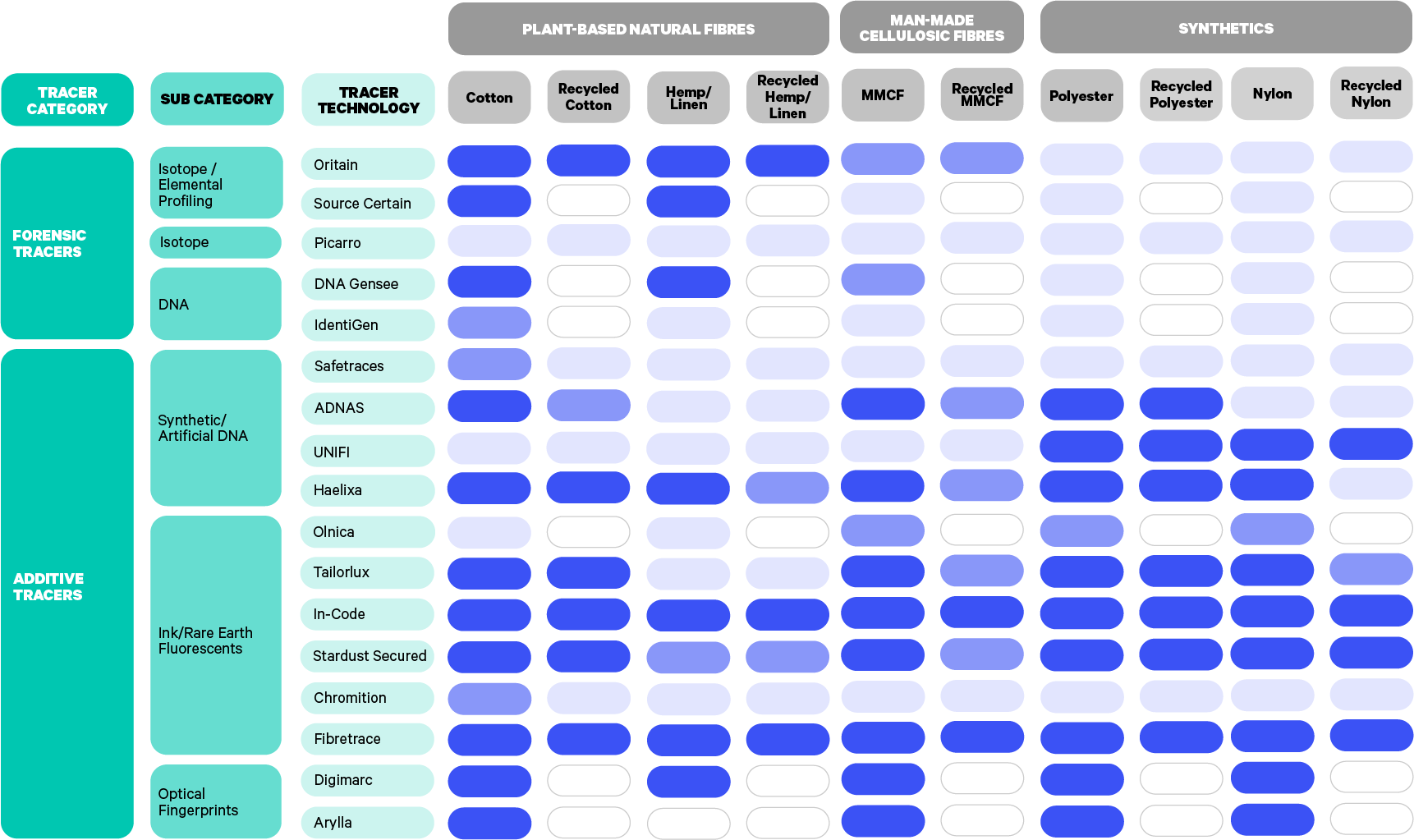

Part 1 analyses the claims made by both the forensic and additive tracer companies on the capabilities tracing different fibre and material types in the fashion supply chain.

Main element of analysis:

- Analysis to show the claimed use-cases per tracer, per fibre/material type (See Figure 5)

The claims from the tracer companies have been classified as follows:

- No claimed evidence that the tracer has worked effectively on the associated fibre/material type

- Technical feasibility: Claimed theoretical evidence that the tracer could work effectively on the associated fibre/material type

- Operational feasibility: Claimed practical evidence (e.g. pilots and/or partnerships) that the tracer has worked effectively on the associated fibre/material

FIGURE 5: Provides an overview of the claims made by both the forensic and additive tracer companies on the capabilities of tracing different fibre types in the textile supply chain.

PART 1: CONCLUSION

Below are the key takeaways in regard to fibre and material use cases. The analysis is grouped into the following categories:

- Forensic tracers

- Additive tracer

- Fibre analysis

FORENSIC TRACERS

Where forensic tracers are useful

- FORENSIC TRACERS ARE USEFUL FOR TRACING ANIMAL AND PLANT-BASED FIBRES

From the claimed fibre and material use cases in Figure 5, forensic tracers indicate good technical and operational feasibility for natural fibres (e.g. cotton, hemp, and wool). This means that they have good capability to verify the geographic origins of plant and animal fibres via their micro-particle detection methodologies. Elemental profiling is necessary for forensic tracers to build provenance databases to verify plant and animal fibre origins. This is to ensure the same micro-particle signatures are not prevalent in other geographic locations of sourced fibres.

- MORE USEFUL FOR VERIFYING GEOGRAPHIC ORIGIN THAN SUPPLY CHAIN ORIGIN

Forensic tracers have been more associated with verifying geographic origin (Tier 4) of plant and natural fibres, rather than supply chain origins (Tier 3-0). This is due to the biochemical properties uptaken by plant and natural fibres at Tier 4 raw material extraction, which can then be more accurately analysed and cross-referenced against new samples taken.

Where forensic tracers are less useful

- NOT AS USEFUL FOR TRACING SYNTHETIC FIBRES

DNA molecular structures, ratios of stable Isotopes (non-radioactive atoms of the same element that hold varying numbers of neutrons such as carbon, nitrogen and others), and trace meddles (including essential elements such as sodium, potassium, zinc, iron Na, K, Zn, Fe) are more present in naturally living (or previously living) fibres rather than synthetic fibres originating from petroleum. Therefore forensic tracers are less useful for tracing synthetic fibres, than animal or plant fibres.

- BUT FORENSIC TRACERS DO HAVE POTENTIAL TO TRACE NATURAL/SYNTHETIC BLENDS VIA ELEMENTAL PROFILING

The process of elemental profiling has the technical capability to validate fibres and materials that have synthetic and natural blends. Elemental profiling is the process of building databases of the trace meddles and isotopic ratios obtained by the fibre, fabric, and/or product through the supply chain journey. In other words, a life-cycle forensic fingerprint that the fibre, fabric, and/or product has picked up on its supply chain journey. Usually for forensic tracers it is associated with building provenance databases of the geographic origin of natural fibres (Tier 4), but can also be applied to building provenance databases of supply chain origins (Tier 3 – 0) for fibres and materials.22

Traceability validation then occurs when samples of the fibre, material, and/or product collected from the supply chain are forensically analysed and cross-checked off-site with the original samples to verify similar bio-chemical elements that created the original elemental profiling database. Some forensic tracers can still identify the type of synthetic fibre if it is blended with a natural fibre, and trace the origin of the natural fibre in the blend (not to confuse the user that forensic tracers can’t work with synthetics mixed and blended natural fibre types).

In contrast to elemental profiling, for natural raw materials such as cotton, there is the technical capability to identify the type of cotton (e.g. Pima or Egyptian Giza cotton), as well as identify whether organic cotton contains GMO-markers. Genomic testing provides information that may help to confirm the cotton content and support label claims that are not possible with only elemental profiling.

ADDITIVE TRACERS

Where additive tracers are useful

- ADDITIVE TRACERS HAVE BETTER ALL-ROUND EFFECTIVENESS ON FIBRES

Additive tracers have claimed better technical and operational feasibility for a larger scope of fibres. This is due to a greater number of tracer technologies in this space, and relates to additive tracers not having to rely on fibres and/or containing bio-chemical elements to provide verification of provenance.

- ADDITIVE TRACERS HAVE GOOD FEASIBILITY FOR SYNTHETIC FIBRE TYPES

A high portion of tracer technologies claim operational feasibility for both polyester and nylon synthetic fibres. This enables good visibility of tracer level verification for sustainability standards and certificates in these fibre landscapes (Global Recycled Standard (GRS) and Recycled Claim Standard (RCS).

- ADDITIVE TRACERS OFFER VERIFICATION FOR RECYCLED FIBRES WHEN APPLIED POST-RECYCLING

Figure 5 sees many tracer technologies effective on virgin fibre supply chains, but not yet on their recycled counterparts. Feasibility for recycled fibres gives insight into use-cases of the stakeholder engagement experience of applying additive tracers post-recycling phase. With the upscaling of recycling capabilities in the fashion and textile industry, this is a big area of opportunity between recycled fibre manufacturers, brands, and tracer technologies looking to verify recycling integrity. This potential for partnership can be applied to recycling standards (Recycled Claim Standard (RCS) and Global Recycled Standard (GRS)). If the user’s focus is to provide verification of recycled content, additive tracers can meet this requirement by being applied to the fibre or material during or after the recycling process, having the same performance as when applied to virgin fibers

- ADDITIVE TRACERS HAVE GOOD CLAIMED FEASIBILITY FOR NATURAL FIBERS INCLUDING COTTON, MAN-MADE CELLULOSIC FIBRES (MMCF), AND LEATHER

Additive tracers claim good operational feasibility and practical evidence of provenance and traceability validation for cotton, MMCF (man-made cellulosic fibres), and leather.

Where additive tracers are less useful

- SUPPLIER ENGAGEMENT ESSENTIAL

The implementation of additive tracers relies on having direct supplier engagement with suppliers and facilities. As the application (and usual detection) mechanisms are on-site, without solidified supplier relations, additive tracers cannot be applied in a managed environment.

FIBRE ANALYSIS

But forensic tracers do have potential to trace natural/synthetic blends via elemental profiling

- COTTON

Cotton holds the best coverage of claimed feasibility by both forensic and additive tracers.

- POLYESTER AND NYLON

Polyester and nylon have great coverage of claimed feasibility by additive tracers.

- MMCF, WOOL AND LEATHER

MMCF, wool and leather has good coverage of claimed feasibility by forensic and additive tracers.

Which fibres were less covered by tracer capabilities

- HEMP, CASHMERE AND MOHAIR

Hemp, cashmere, and mohair have less coverage of claimed operational feasibility by tracers, but optimistic coverage for technical feasibility. This brings exciting opportunities for testing in pilots and projects for the future, and for tracer companies to pursue collaborations with associated-standards (e.g. Responsible Mohair Standard (RMS).

Developments on the horizon

- OPPORTUNITIES FOR FURTHER PILOTS AND PARTNERSHIPS

There are exciting opportunities to explore collaborations and pilots for tracer technologies claiming technical feasibility for certain fibres (see Figure 5 to highlight which tracer technologies have claimed technical feasibility on certain fibres and materials). This indicates that the traceability potential is there, and partnerships can be made to pursue sustainability agendas for brands, retailers, and suppliers.

- COLLABORATIONS WITH SUSTAINABILITY STANDARDS AND CERTIFICATION BODIES

In addition, there are exciting opportunities to explore collaborations and partnerships between tracer technologies, sustainability standards and associated certification bodies.

- TRACEABILITY VERIFICATION OF RECYCLED FIBRES WHEN APPLIED PRE-RECYCLING

As mentioned above, there is a large potential for traceability verification of recycled fibres by additive tracers, when applied after chemical/mechanical recycling for recycled process verification. Unfortunately due to many additive tracer companies still testing their efficacy to sustain through chemical and recycling processes, at present no wider conclusions can be drawn to applying additive tracers prior to recycling, and detecting after the fibre, material, and/or product has been recycled. It is clear that mechanical recycling processes have less impact on additive tracer substances than chemical recycling. Traceability verification of recycled fibres (when applied pre-recycling) is an important space to watch as the post-gate circular economy grows within the fashion and textile industry.