The Textile Tracer Assessment

Part 2: Supply Chain Coverage: Application

Part 2 analyses the claims made on the application processes of the tracer technologies within the fashion supply chain, focusing on one main element and various sub-elements.

Main element of analysis:

- The scope of supply chain coverage for application processes (See Figure 6)

Analysing claims made by tracer companies of where in the fashion and textile supply chain the tracers can be detected effectively. The variables being the different tiers of the supply chain.

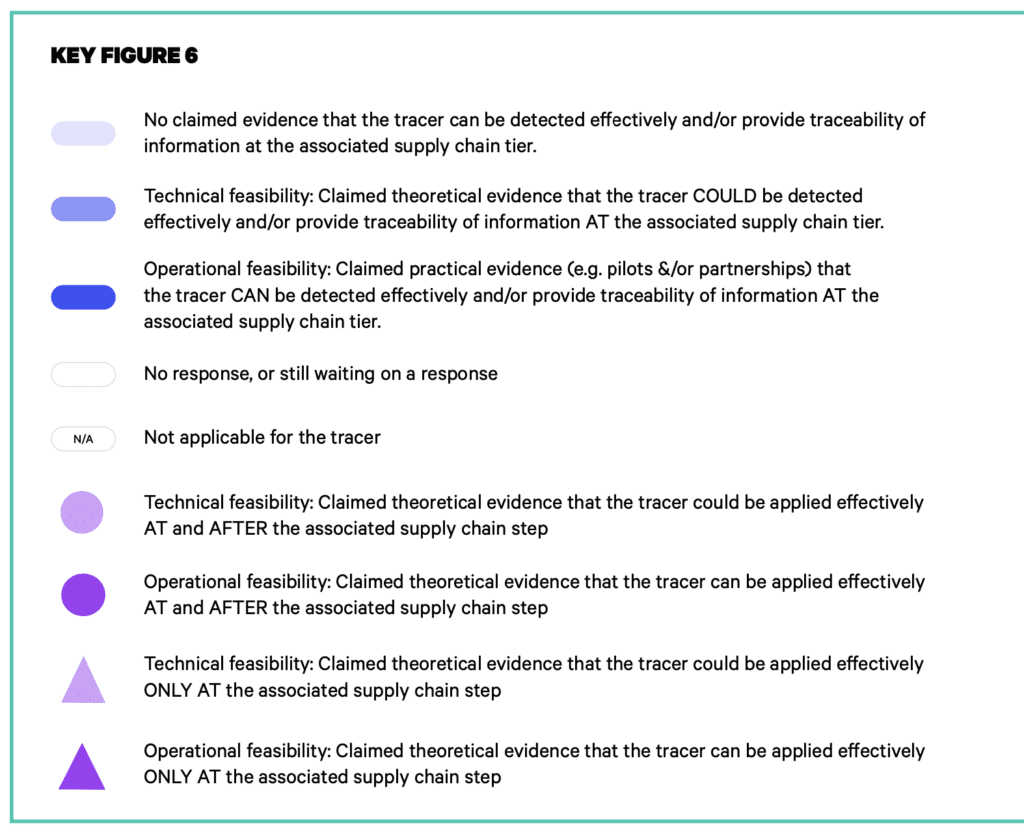

The claims from the tracer companies have been classified as follows:

- Technical feasibility: Claimed theoretical evidence that the tracer COULD be applied effectively AT and AFTER the associated supply chain Tier

- Operational feasibility: Claimed theoretical evidence that the tracer CAN be applied effectively AT and AFTER the associated supply chain Tier

- Technical feasibility: Claimed theoretical evidence that the tracer COULD be applied effectively ONLY AT the associated supply chain Tier

- Operational feasibility: Claimed theoretical evidence that the tracer CAN be applied effectively ONLY AT the associated supply chain Tier

Sub-elements of analysis:

- Application processes of the tracer to fibres and materials in the supply chain.

- Stakeholders in control of the application process

- How the additive tracer is transferred from the technology provider to user

- Referring to how the tracer substance (see glossary) is transported from the tracer company to the user

- Who determines the volume of tracer substance applied, and how much is needed to be effectively detected later in the supply chain

Graphic showing the textile supply chain tiers: Tier 4 to Tier 0

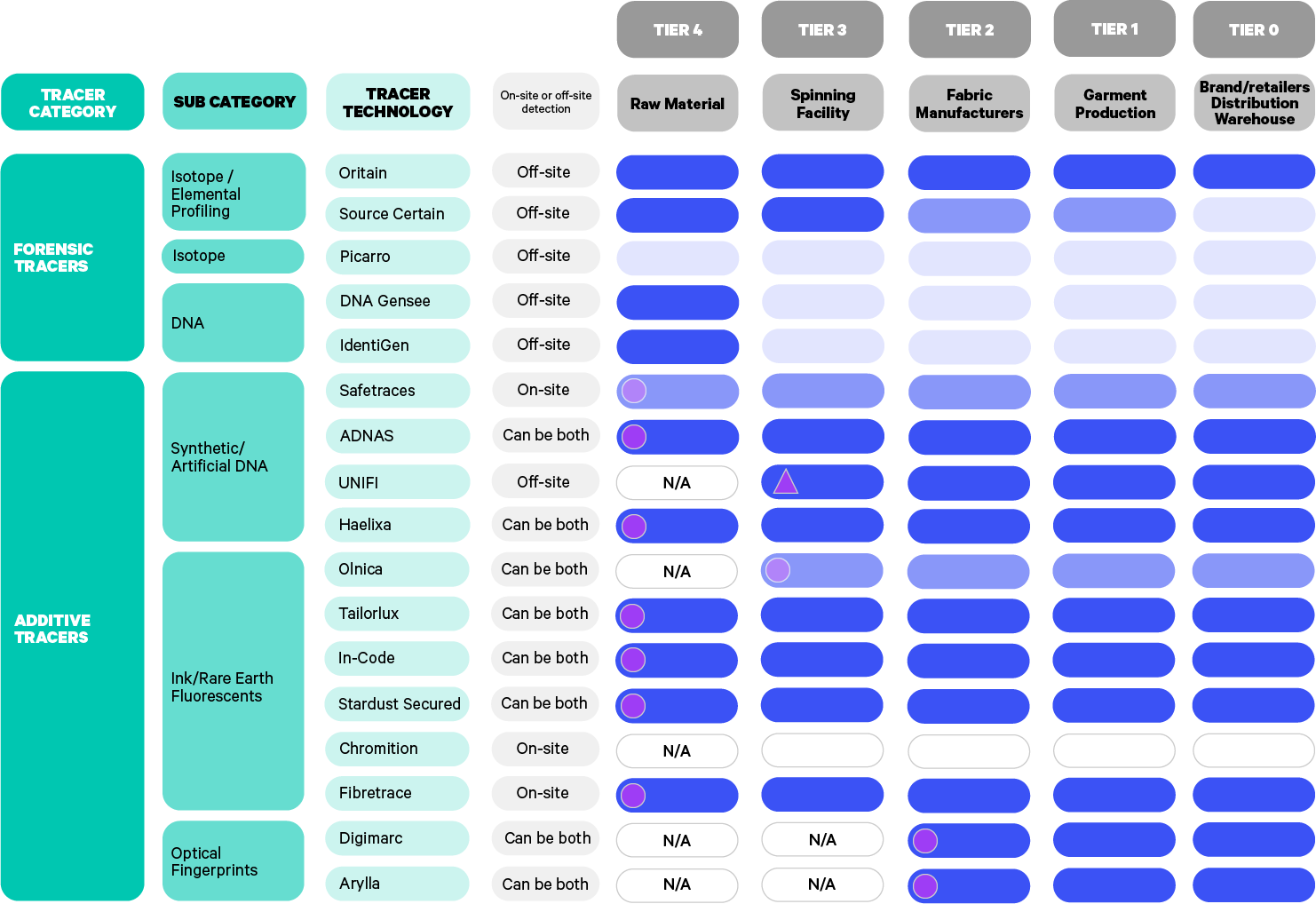

FIGURE 6: Table to show where in the fashion and textile supply chain, the tracers can be applied and detected effectively and/or provide traceability of information.

PART 2: CONCLUSIONS

Below are the key takeaways in regard to supply chain coverage: application capabilities. The analysis is grouped into the following categories:

- Forensic tracers

- Additive tracer

- Application capabilities

- Application processes

FORENSIC TRACERS

- No application process therefore less supply chain burden

For forensic tracers nothing is added to the fibre, fabric, or garment on the supply chain floor. Therefore there is no application process. Supplier engagement may still be required if the user and forensic tracer company wish to build a provenance database in order to cross-reference samples for validation processes for geographic and supply chain origins.

ADDITIVE TRACERS

Application capabilities

In reference to Figure 6 based on the claims made, all other additive tracers can implement their tracing technologies from Tier 3 (spinning facility) to Tier 0 (Brand and Retailers), apart from the optical fingerprints sub-category. Some have proven technical or operational feasibility to apply their tracer technology beyond, from Tier 4 (Raw Material). For the user, this indicates there are several options in the additive tracer category to provide traceability validation from the extraction of fibres and raw materials and from spinner facilities.

A majority of tracer technologies claimed both theoretical and/or operational feasibility that their tracer can be applied “at and after” the initial supply chain step of application. This shows a large degree of flexibility to cater for the needs of the user e.g. if the user wants to use synthetic/artificial DNA tracers or ink/rare-earth material fluorescent tracers, but only has supply chain engagement up until Tier 2 or 3, it is still possible to implement as they can be applied to all fibre, yarn, and fabric material compositions.

- OPTICAL FINGERPRINTS APPLICATION CAPABILITIES FROM TIER 2

Tracers in the optical fingerprints sub-category who apply proprietary inks and digital watermark serialisation using digital presses, laser etching systems, and industrial inkjet devices, can only be applied on fabrics or labels. Therefore they have a focused application capability from Tier 2 – 0. For the user this fits well for providing traceability integrity from Tier 2 (Manufacturers) and Tier 1 (Garment Producers).

- SYNTHETIC/ARTIFICIAL DNA AND INK/RARE-EARTH MATERIAL FLUORESCENTS APPLICATION CAPABILITIES FROM TIER 4

Synthetic/artificial DNA and ink/rare-earth, material fluorescent tracers have capabilities to be applied, and therefore verify information, further back in the supply chain. This is because their tracer compounds and substances have been designed to withstand Tier 3 and 2 manufacturing processes.

- STAKEHOLDER ENGAGEMENT, ONBOARDING, AND A SECURE APPLICATION ENVIRONMENT IS ESSENTIAL

A key takeaway of the application process for additive tracers is that training and onboarding of stakeholders is needed to implement and to create a secure application environment for effective traceability implementation. Therefore a prerequisite of application is supplier engagement, training, and logistical organisation.

Application processes

Additive tracers are applied to supply chain coverage: application capabilities in a variety of ways depending on the tier of the supply chain in question and associated manufacturing and design process. Sprayed mists, liquid-inks, pigments, and optical fingerprints are applied to fibres, materials, garments, and/or labels be detected further down the supply chain.

- MANUAL VS MECHANICAL (IN-LINE) APPLICATION OF ADDITIVE TRACERS

A key distinction is between manual and in-line application processes e.g. applying additive tracers manually on the supply chain floor vs mechanically through in-line machinery. It appears the former is more common as mechanical application of additive tracers is at the early stages of integrating into supply chain manufacturing processes. Looking forward, up-scaling mechanical (in-line) application machinery within ginning, spinning, and fabric manufacturing facilities for additive tracers is an exciting space for expanding traceability integration for suppliers. It is also a collaborative opportunity for brands/retailers who are sourcing from the same facilities, and who wish to share costs on traceability implementation. Based on the claims made, many application mechanisms for additive tracers can be automated on supplier machinery for efficiency at a larger scale.

- SYNTHETIC/ARTIFICIAL DNA TRACERS APPLIED AS A SPRAY MANUALLY

Synthetic/artificial DNA tracers are applied either through automated spray systems or, when not feasible, manually through spraying mists onto fibres and materials on the supply chain floor. This can take place from Tier 4, raw material extraction. They can also be applied together with spinning oils in tier 3 or embedded within synthetic fibres during their manufacturing processes in Tier 4.

- INK/RARE EARTH FLUORESCENTS:

Ink/rare earth fluorescents are embedded in or on fibres and materials through various application methods. Tracer substances can be applied within the many fibre and yarn manufacturing processes. For synthetic, natural, and animal fibres, application can occur at Tier 4 – (raw material source), Tier 3 – (spinning stage), or later in the supply chain. Advice is to contact tracer companies directly for more information on the potential of application mechanisms, as most tracer companies are flexible to the users demand.

- OPTICAL FINGERPRINTS “(non-exhaustive)

Nano invisible-ink markings printed on product labels (Arylla) are applied by the label providers using inkjet stations to print ink on companies’ labels.

Digital watermarks/serialisations (Digimarc) are applied using digital presses, laser etching systems and industrial inkjet devices. Both can only be applied effectively to finished fabrics and garments (Tier 2-0).

- THE VOLUME OF TRACER SUBSTANCE APPLIED IS DEPENDENT ON IT’S EFFICACY AND EFFECTIVE DETECTABILITY LATER IN THE SUPPLY CHAIN

This is highly dependent on the efficacy capabilities of the additive tracer substance itself (spray mist, liquid inks, and pigments etc). The variations are the amount of tracer applied, and the size of the fibre, material and/or product needed for the tracer to be effectively applied and detected later in the supply chain.

- HOW MUCH TRACER SUBSTANCE OR FABRIC IS NEEDED FOR EFFECTIVE APPLICATION

For additive/synthetic tracers and ink/rare earth fluorescent tracers markings tracer substances are applied in parts per million/billion.

For optical fingerprint tracers, markings are printed on fabric/labels within boundaries of a few cm squared.

- SUPPLIER ENGAGEMENT A PREREQUISITE FOR IMPLEMENTATION

Solidifying supplier relations is an essential first step prior to the use of additive tracers.