The Rise of Reusable Packaging: Understanding the Impact & Mapping a Path to Scale

Single-use vs Reusable System

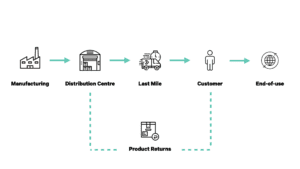

FIGURE 1

The diagram above shows the journey of a package from the point of manufacturing through until its end-of-use in e-commerce. Globalisation has meant that packages are travelling further, through longer and more complex logistics networks.31 Customers are increasingly demanding faster, more convenient shipping methods whilst brands are jostling for a competitive advantage through providing unique experiences in the unboxing process. In this e-commerce driven market, packages are handled 20 times more frequently than in a traditional retail market, where an item moves from the manufacturing to a retail store on a pallet.32 Whilst the current system is highly optimised and convenient in delivering packages to the consumer, the infrastructure does not yet exist to ensure the packaging used is reused or recycled.

Resealable Low Density Polyethylene (LDPE) mailers have become the standard packaging solution across most e-commerce categories, with the fashion sector being no different.33 While presenting a low- cost, protective and lightweight solution, such mailers have a very short lifespan and are not designed to be reused multiple times. Moreover, robust recycling solutions do not exist on a global scale, with very few effective biodegradable alternatives, thus resulting in the generation of a huge amount of landfill waste.

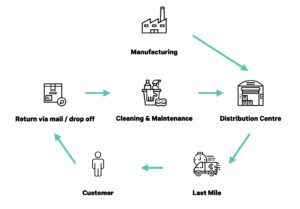

THE REUSABLE SYSTEM

The reusable system of e-commerce packaging represents a closed-loop process, transforming packaging from a single-trip to a multi-trip asset. Despite the nascency of innovation, there are two slightly different models being implemented at this time. In both contexts, the packaging follows the same journey as single- use packaging to the point of the customer – from manufacturing, to distribution centre and through last mile delivery. However, once the customer receives the package, they are instructed to return the package, either via a mailbox or drop-off point. In the centralised system, this package is first transported to an additional node where it is cleaned and any necessary repairs are made. From that point, it is sent back to the brand’s distribution centre and the cycle starts again. This approach is being used by RePack, who have their European Returns hub located in Estonia.34

RePack (Finland) leases packaging for products in B2C e-commerce. Once the consumer receives the product – the packaging, which comes with a return label offered by RePack, is folded and sent to the company by regular mail. RePack then cleans and checks the quality of the packaging before directing it back to stores/DCs. RePack offers its customers a discount coupon towards the next purchase in any partner store. The brands choose how the reusable packaging is offered to customers, e.g. as a paid option at checkout, for free over and expended amount, or for free with the company absorbing the delivery cost.

FIGURE 2

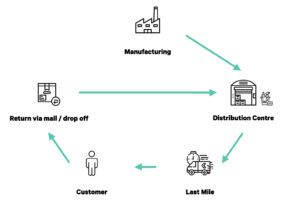

In the decentralised system, the packaging moves directly back to the distribution centre, with cleaning and maintenance taking place at the DC. This approach is being employed by Returnity and LimeLoop.

Returnity (US) sells reusable boxes, bags and envelopes. The company produces customised B2B packaging, in which the packaging is kept in circulation. Returnity primarily serves (what they refer as) the ‘circular-adjacent’ economy – that is, customers who have an element of circularity inherent in their process. For example, from the DC to store, back to DC. It had also tested in B2C market segments, most prominently serving clients with circular business models – such as rental or leasing models for apparel. This provides greater assurance that the package is going to be returned.

LimeLoop (US) is aiming to realise the bigger vision of sustainable shipping logistics for e-commerce through data-driven logistics and reusable shippers. GPS sensors are placed in the packaging, providing an overview of where shipments are, and where/when they have been opened, providing inventory security and visibility to the supply chain. This approach helps to marry sustainability and profitability – reducing the impact and plastic wastage through reusables and helping customers to reduce their inventory loss. Customers rent the standardised reusable packaging from LimeLoop, which also gives access to the data.

FIGURE 3

The reusable and returnable packaging being developed by innovators are durable, water-repellent and secure, commonly manufactured with a high quantity of recycled content (material used is dependent on innovator). Given the longevity of the packaging, it allows for greater investment in the asset, creating a better user experience and helping brands to gather data that is not possible through single-use packaging. For example, the French LivingPackets have created a package that can withstand 1,000 journeys – incorporating sensors, a secure locking system, and a camera to monitor the shipment contents and conditions during transit.35

LivingPackets (France) are bringing smart packaging technology to market. They have launched a foldable smart shipping box (‘The Box’) for consumer per-to-peer shipments with a design life of 1,000 journeys. The Box incorporates an integrated load securing systems, an e-ink display to update address data and logistics-relevant information, sensors and an integrated camera to monitor the shipment contents and environmental conditions (temperature, humidity and shock) during transit.