The Rise of Reusable Packaging: Understanding the Impact & Mapping a Path to Scale

Methodology

For the purposes of this study, the ‘Fast-Track’ Life Cycle Assessment (LCA) methodology, developed by the Technical University of Delft, was used to compare the environmental impact of single-use versus reusable packaging systems.

Life Cycle Assessment (LCA) is a methodological framework for estimating and assessing the environmental impacts attributable to the life cycle of a product. It provides systematic framework that helps to identify, quantify, interpret and evaluate the environmental impacts of a product, function or service in an orderly way. It is a tool which can be used to compare existing products or services with each other, which may indicate promising areas for improvement in existing products and which may aid in the design of new products.

– European Commission (2020)

It was selected as an appropriate methodology as it enables the comparative analysis of different systems. In this context, a reusable packaging system is not a material innovation, as it uses known materials with existing impacts, therefore a full LCA that carries out a comprehensive audit of the production was not necessary. In other words, a Fast-Track LCA focuses on what impact to calculate, rather than how to calculate impact.36

Impact data regarding the material production, transport and end-of-life was taken from IDEMAT – an open-source set of peer-reviewed databases containing Life Cycle Inventory information from TU Delft.37 A combination of proprietary analysis and publically available data was used to best estimate data-points such as percentages of packages returned, proportion of packaging landfilled versus incinerated (in the single-use context) and so on. Therefore, as with any LCA, there are a series of assumptions that underpin the analysis; however, all steps were taken to ensure the rigour of the data used.

The functional unit for this study was 1000 e-commerce deliveries, with the appropriate sizing to cover a small e-commerce order (3 t-shirts packed efficiently).38

The functional unit is a key element of LCA which has to be clearly defined. The function unit is a measure of the function of the studied system and it provides a reference to which the inputs and outputs can be related. This enables comparison of two essential differs systems.

– European Commission (2020)

The system boundaries for the Fast-Track LCA comparison is based on a Cradle to Grave system – that is, measuring the unit processes within the material and manufacturing phase (cradle), transportation, use phase, and finally end-of-life phase (grave). A more detailed overview of the system boundaries for both the single-use and reusable case can be found in the Appendix.

THE BASE CASE

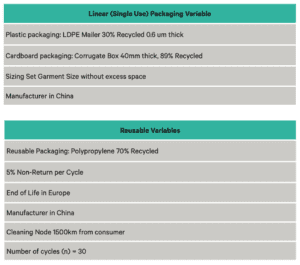

In order to conduct a comparative analysis assessing the impact in changing one (or more) variable(s), it is necessary to agree on a certain set of variables that stay consistent throughout – otherwise known as the base case. These can be seen in the figure above.

In the single-use packaging example, the recycled content was set at 30% in the Low Density Polyethylene (LDPE) mailer. Despite there being no publicly available data on the average of recycled content used in e-commerce packaging, upcoming UK legislation is mandating at least 30% recycled content in all plastic packaging – thus representing an aspirational but achievable figure to use.39 When making the comparison between cardboard and reusables, a 40mm thick, 89% recycled cardboard example was used. This is in keeping with European Federation of Corrugated Board Manufacturers’ (FEFCO) finding of average recycled content of corrugated cardboard as of 2017.40

In both contexts, a ‘small’ package was used – that is, a package of 3 t-shirts packed with no excess space, optimising the size of the package. It is worth noting that packaging optimisation is a crucial barrier to lowering the environmental impact of single-use packaging – with DHL (2019) estimating over a quarter of packaging is empty space in fashion e-commerce packages, due to the lack of structural rigidity of packages.41 However, for purposes of consistency, optimised packaging sizes were used.

In the reusable context, we averaged data from innovators and came to a figure of 70% recycled polypropylene (PP) as the material composition for the packaging. In the centralised model, the cleaning node was set at a distance of 1500km, accounting for a distance across multiple European countries – or across approximately one third of the USA. In this model, the manufacturing of the package occurred in China, therefore transportation emissions from that point to the distribution centre were included. In the base case, a 5% non-return rate was used. A 5% non-return rate would suggest that, across a cycle of 1000 packages, 950 packages would be returned. Return rates can vary significantly between different reusable packaging systems and use-cases, but 5% is an ambitious and aspirational target.42

In setting the base for reusable packaging, a hypothetical number of cycles had to be chosen to represent the ‘life’ of a reusable packaging. Whilst reusable packaging innovators promote the ability for their package to be able withstand hundreds, even thousands of cycles, there is a point at which the per cycle reduction of carbon emissions of reusable packaging versus single-use packaging levels off.

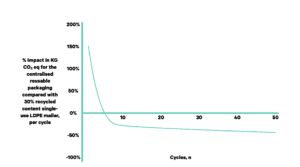

From the graph below, it is clear that there are diminishing returns for the reduction of CO2 eq in the reusable system versus single use plastic mailers for each additional cycle. After approximately 30 cycles, the CO2 eq savings compared with a single-use plastic mailer plateaus. For that reason, 30 cycles was selected as an appropriate base case for reusable packaging. Also of note from this graph is that, presuming a 5% non-return rate, a reusable package must fulfil more than 4 cycles before it presents a reduction of CO2 eq emissions compared with a LDPE mailer with 30% recycled content.

FIGURE 4