The Rise of Reusable Packaging: Understanding the Impact & Mapping a Path to Scale

Considerations for Implementation

Considerations for Implementation

The purpose of this section is to take the findings from the impact assessment and present the key considerations for implementing a reusable system to ensure its future potential success.

The above analysis has demonstrated that certain factors can drastically influence the viability of reusable packaging for fashion e-commerce, whilst having significant consequences from an economic perspective too. Therefore, considerations must be made and action must be taken to ensure reusables are implemented in an effective manner. In addition to the impact assessment, interviews were also conducted with Fashion for Good brand partners and innovators who have piloted reusable packaging solutions to understand the key lessons learnt from implementation.

Adopting reusable packaging is a systems-level change that requires buy-in from all stakeholders across the value chain – including innovators, brands, 3PL companies, consumers and policy-makers.51 Only with the participation and collaboration of all parties will we be able to see the potential impact of reusables come to fruition.

Packaging is really about systems. It’s not about the product, it’s also about process and participation. Only with that perspective in mind are you going to see how reusables work on a system level.

Michael Newman, Founder, ReturnityMAXIMISING RETURN RATES

ISSUE:

Ensuring high rates of return for the packaging is central to both the environmental and economic viability of reusable packaging.

From Sensitivity test #2, we can see that a 0% non-return rate can cause a 51% reduction in CO2 eq compared with single-use packaging; however, a 40% non-return rate increases CO2 eq emissions by 40% (travelling 400km from DC to consumer).

However, getting packaging returned is more complicated than it initially may seem; it is a behavioural change that requires a fundamental re-thinking of how we currently interact with packaging. Given the nascency of the innovation, coupled with the ubiquity of single-use packaging, many consumers have not engaged with reusable packaging in the fashion e-commerce context.

Reusable packaging is more complicated than just sending a package back and forth - there is a key consumer education piece to increase return rates.

Karla Jabben, Corporate Responsibility Manager, OttoTherefore, a central part of the undertaking in transitioning to a reusable system is to inform consumers, communicate its importance, and help them through the process. It may seem obvious, but simple messaging that clearly informs the consumer on how to return the empty package, or how to return the package containing product returns, was cited as a crucial lever to increase return rates of packaging.

Innovators must collaborate with brands to think about communication; how to communicate with consumers, what to communicate, where to communicate and when to do it. There is not one silver-bullet approach to communication, but instead it is specific to the brand’s consumer group and therefore requires collaboration between the brand and the innovator to implement it. Communication more broadly has a role in educating consumers on the potential benefits of reusable packaging. In doing so, interviewees cited that consumers become more motivated to engage in the process, thus leading to an increase in the return-rate. Informing consumers on the importance of reusable packaging is a crucial step-change in transitioning to a system whereby reusables are commonplace.

To make [reusable packaging] work, it’s not something that Zalando can do by itself, it requires packaging innovators and the consumers.

Andrea Roxin, Manager Environmental Sustainability, ZalandoBeyond communication, incentivisation is commonly used as a method to motivate consumers to return the packages. One incentivisation example being implemented by brands and retailers is the use of a reward system. RePack are the biggest proponents of this approach – they have created a marketplace where consumers can redeem a discount code on future purchases once their package has been returned. The marketplace features all RePack participating brands and retailers – encouraging consumers to discover other brands utilising reusable packaging. The discount code can also be redeemed in the form of a charitable donation, if preferred. It is difficult to quantify the impact on return rates that the discount- code incentivisation presents; however, RePack cited that it was significant in increasing returns, whilst improving the customer experience of using reusable packaging.

The use of discount codes for incentivising returns can be considered one tool amongst many to engage and motivate consumers in the short-term; however, other considerations are crucial when thinking about scaling reusable packaging in the future. The most commonly cited of those was to increase the number and type of return points. The benefit in doing so is multi-faceted; on one hand it increases the convenience for consumer returns, whilst also helping to reduce the costs associated with the reverse logistics. It facilitates the pooling of packages before being sent back to the DC, increasing the scale and thus reducing the per unit cost of the returns. The aggregation of packages also has positive consequences on the environmental impact, reducing transportation emissions. It requires collaboration between innovators, 3PL companies and brands to increase the density of return points, placing customer-centricity at the heart of the reusable system.

Scale allows the system to thrive - a system with high densities of convenient drop-off points with agnostic shippers becomes a fluid system that normalises reusable packaging.

Ashley Etling, CEO & Co-founder, LimeLoopOne such example of a similar model operating in the fashion industry, but outside of reusable packaging, is the US-based Happy Returns. Happy Returns’ ‘Return Bar’ system allows users to return their order in over 2,500 locations across the USA, initiating the exchange, refund or store credit immediately.52 Once collected, the returns are aggregated and shipped to regional Return Hubs for sorting and processing.53 Although it is currently focused on e-commerce returns, this type of innovation could be applied in the returning of reusable packaging in the future.

INTEGRATION INTO BRAND’S DISTRIBUTION CENTRE (DC)

ISSUE:

Reusable packaging can present challenges in integrating into the brand’s DCs, given their optimised systems are set-up for single-use packaging.

Many (large) brands have optimised systems and automated processes for fulfilling e-commerce orders in their distribution centres. The introduction of reusable packaging can require changes to be made to the incumbent processes, sometimes at the expense of operational productivity.54 Warehouse workers may have to spend a longer time packing, leading to increased total labour costs.55

There is no doubt that the introduction of reusable packaging will lead to changes in the operations and logistics for brands. Moreover, given that each brand has a unique approach to fulfilling e-commerce orders, there is no one-size fits all solution to overcoming this challenge.

Crucial to Returnity, given the brand is purchasing the asset, is making the integration into their [the brand or retailer’s] current system as seamless as possibile.

Micheal Newman, Founder, ReturnityRegardless of the current system, creating a seamless integration into existing processes is crucial for the scalability of reusable packaging. One such innovator aiming to overcome the challenges with warehouse integration is LimeLoop. From the outset, LimeLoop has been creating ‘layers of technology’ to make a more seamless integration into the brand’s warehouse management system, as well as integrating into the e-commerce system. Innovation in integration of reusable packaging, especially where it fits into current equipment and processes, should be a top priority by innovators to save on manual labour costs. The integration of reusables requires brands to pilot the technology and open up their distribution centres, allowing innovators to see how their current systems operate and then deliver a product to fit that. The experience of piloting and bringing product to market will help to reveal the challenges with the current system, allowing innovators and brands to iterate and improve the offering. Only with this level of collaboration and co-development will all stakeholders benefit from the innovation.

Piloting with brands is the best way to understand the success areas and challenges. It is super important that the brands are willing to test, fail and try again.

Clémence Avignon, Sales Marketing Manager, RePackINEFFICIENCY IN THE CURRENT REUSABLE SYSTEM

ISSUE:

There are some inefficiencies in the reusable system that should be overcome to further optimise the offering.

Given the nascency of reusable packaging for e-commerce in the fashion industry and the complexity of the system, there are still some inefficiencies that can be eradicated to further optimise the reusable packaging system. These can be summarised as follows:

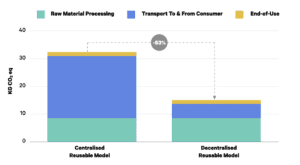

- Transition from centralised to decentralised system – by moving to a decentralised system, thus integrating cleaning and maintenance within the DC, transportation distances are reduced. In turn, so are transportation emissions, reducing the overall environmental impact of the reusable system. From the diagram below, we can see that integrating the cleaning node into the DC can reduce per cycle CO2 eq emissions by over 50%.

- Increase the recycled content of the package – in the decentralised model, we can see that the raw materials and processing emissions account for over 60% of the total per cycle emissions. Given in this context the recycled content is set to 70%, there is room to further innovate and integrate more recycled content into the product to reduce the emissions associated with the raw materials and processing stage. For example, LimeLoop is making their reusable packing from 100% recycled billboard vinyl material, diverting waste from landfill and reducing the burden on virgin resources.

FIGURE 12