Coming Full Circle: Innovating towards Sustainable Man-Made Cellulosic Fibres

Executive Summary

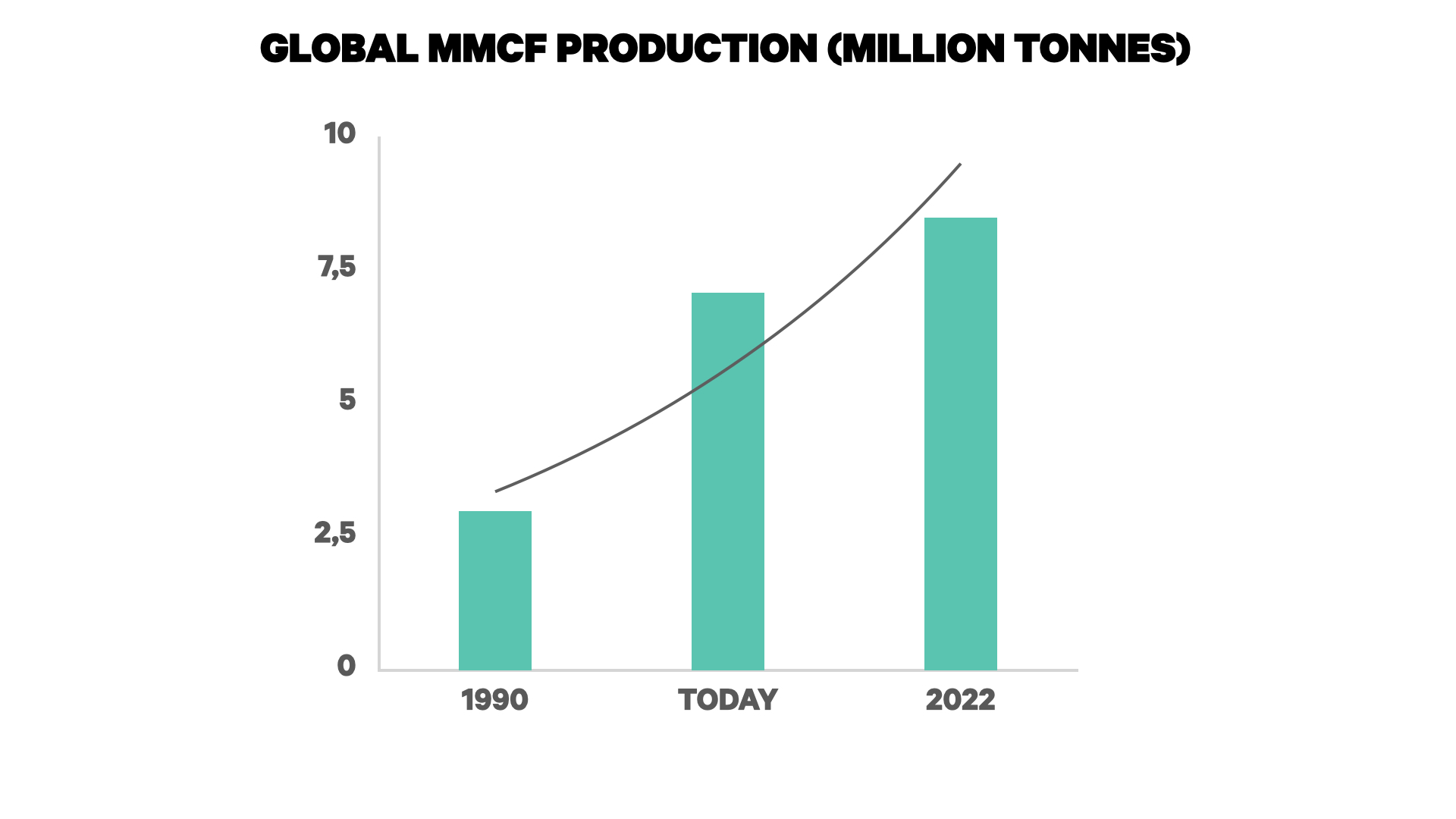

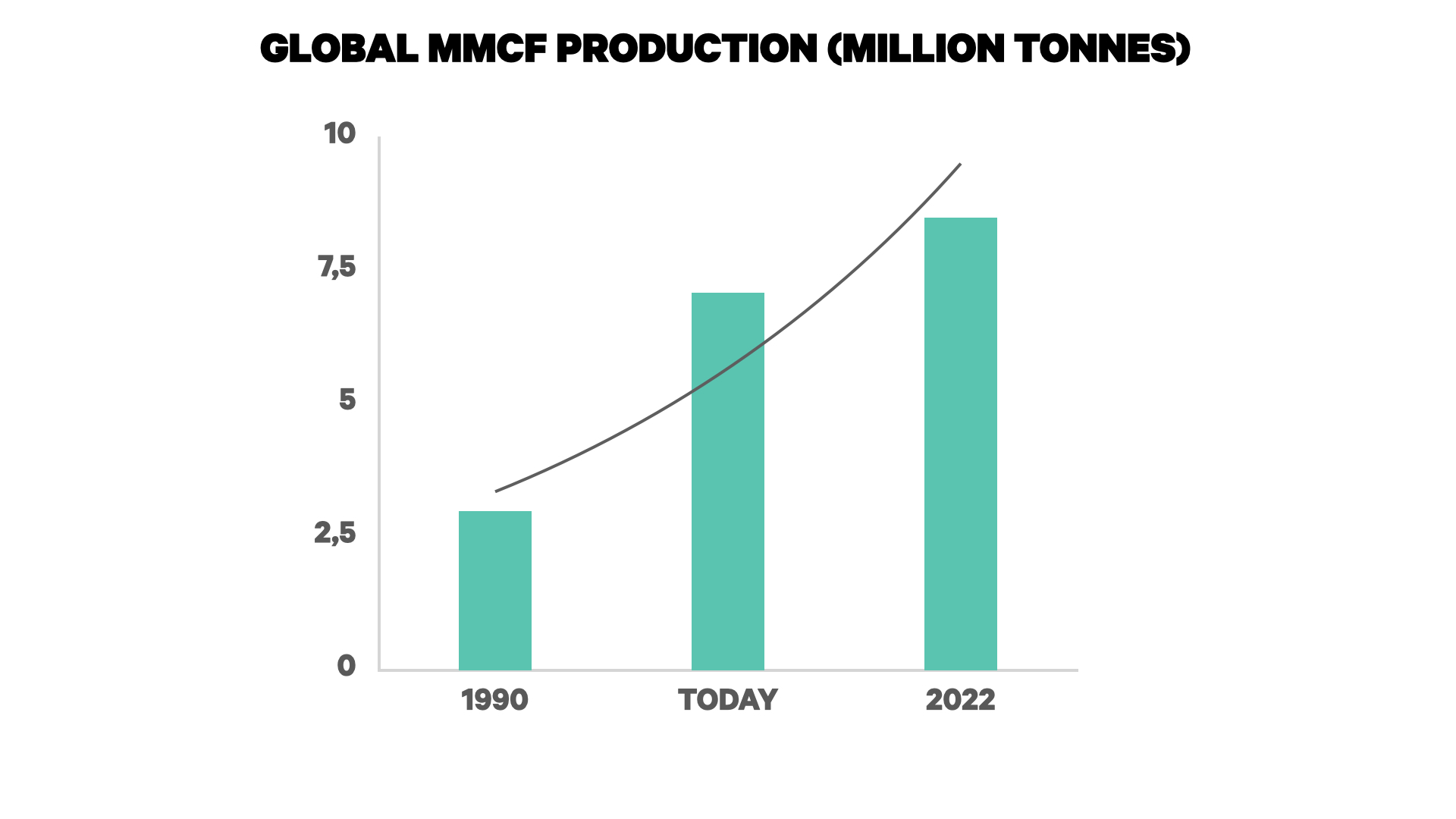

Man-Made Cellulosic Fibres (MMCF), which are most commonly derived from wood, have the third largest share in global fibre production after polyester and cotton. They are a set of fibres with increasing importance – MMCF production has doubled in the last 30 years and is forecast for continued growth over the coming years. MMCF production has great potential from a sustainability perspective; moving production away from oil-derived synthetic fibres and reducing the depletion of freshwater through reduced cotton cultivation.

Introduction

The importance of MMCF production remains a challenge

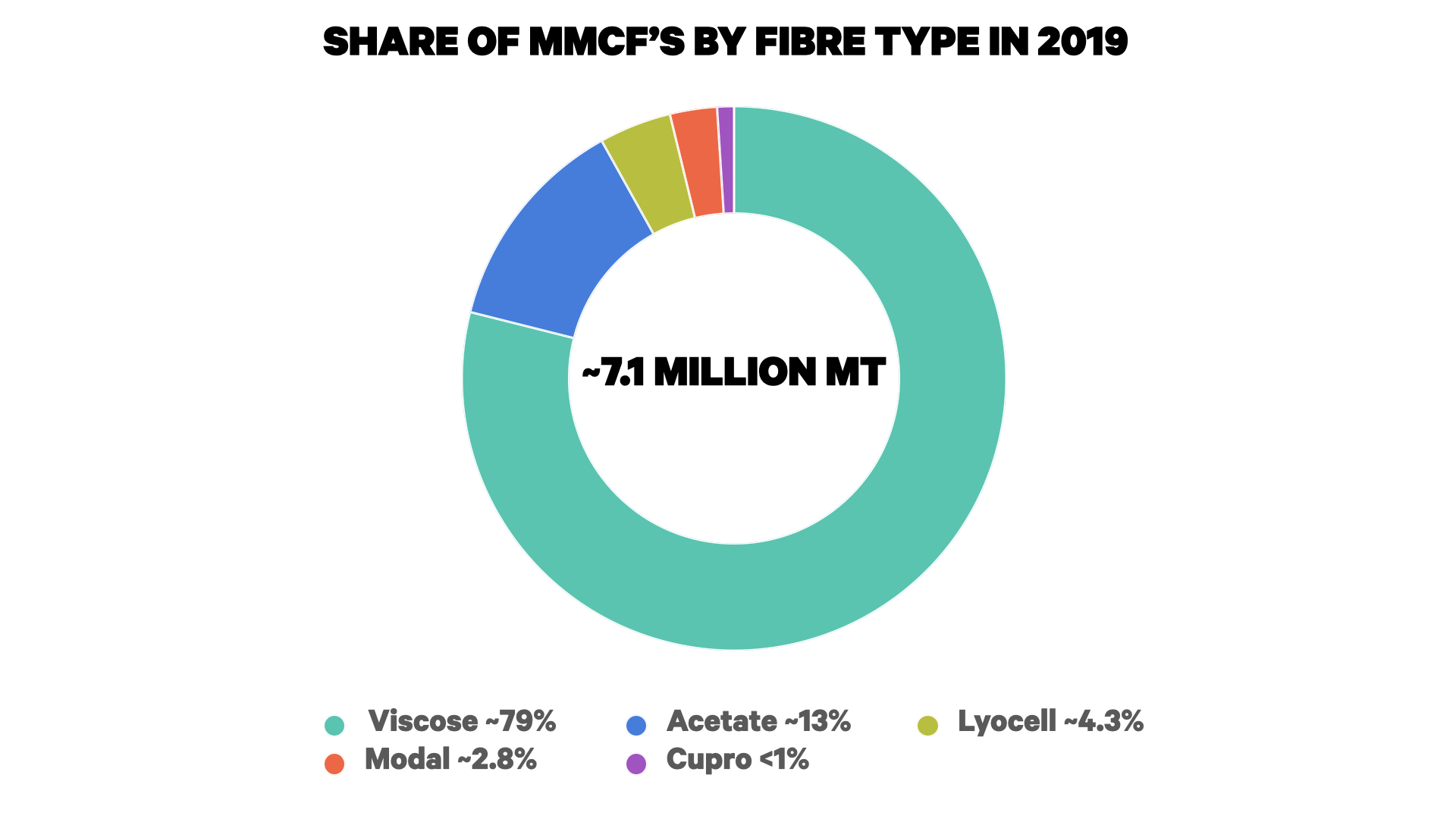

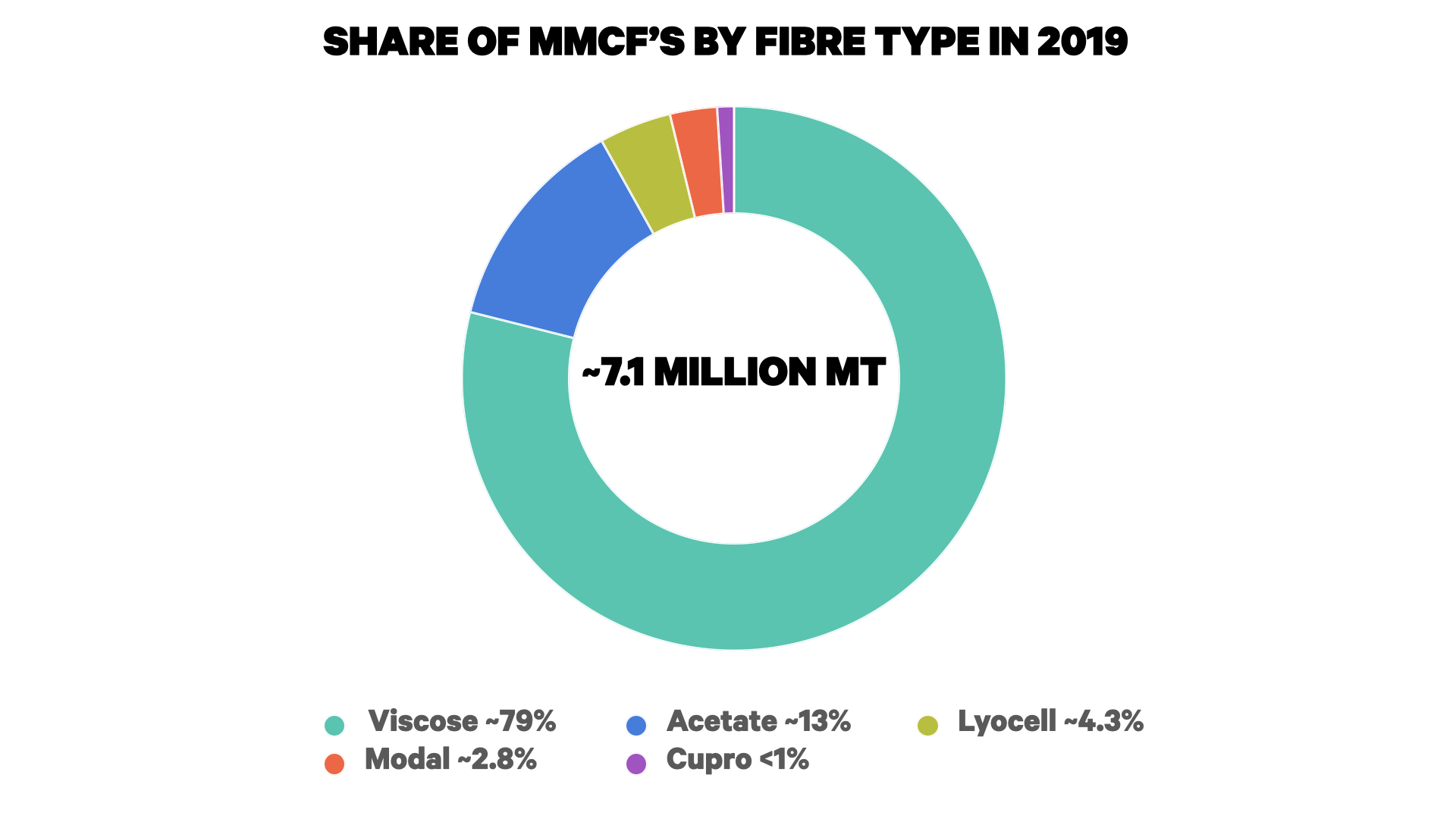

Man-made cellulosic fibre (MMCF) are a group of fibres that are conventionally derived primarily from wood, and in some cases other sources of cellulose, such as bamboo or other plant matter. Cellulose is found in the walls of plant cells, helping plants and trees to stay upright. It is also a key component of cotton fibres, in which it is found in extremely pure form. Cotton is an example of a ‘natural’ cellulose fibre and is processed differently from MMCF – with the latter following a dissolution and extrusion process, thus being referred to as ‘man-made’. In the majority of MMCF production, wood is mechanically shredded and then processed multiple times into sheets of cellulosic ‘pulp’. These sheets are then dissolved to form a viscose solution, which is extruded through spinnerets in a wet spinning process into fibre.

Key Issues

In man-made cellulosic fibre production

The current system of virgin MMCF production has issues that can be broadly categorised into three key areas:

- When sustainable forestry practices are not followed, the extraction of raw material is contributing to the continued deforestation and logging of forests, particularly important are ancient and endangered forests, as well indigenous communities’ traditional lands;

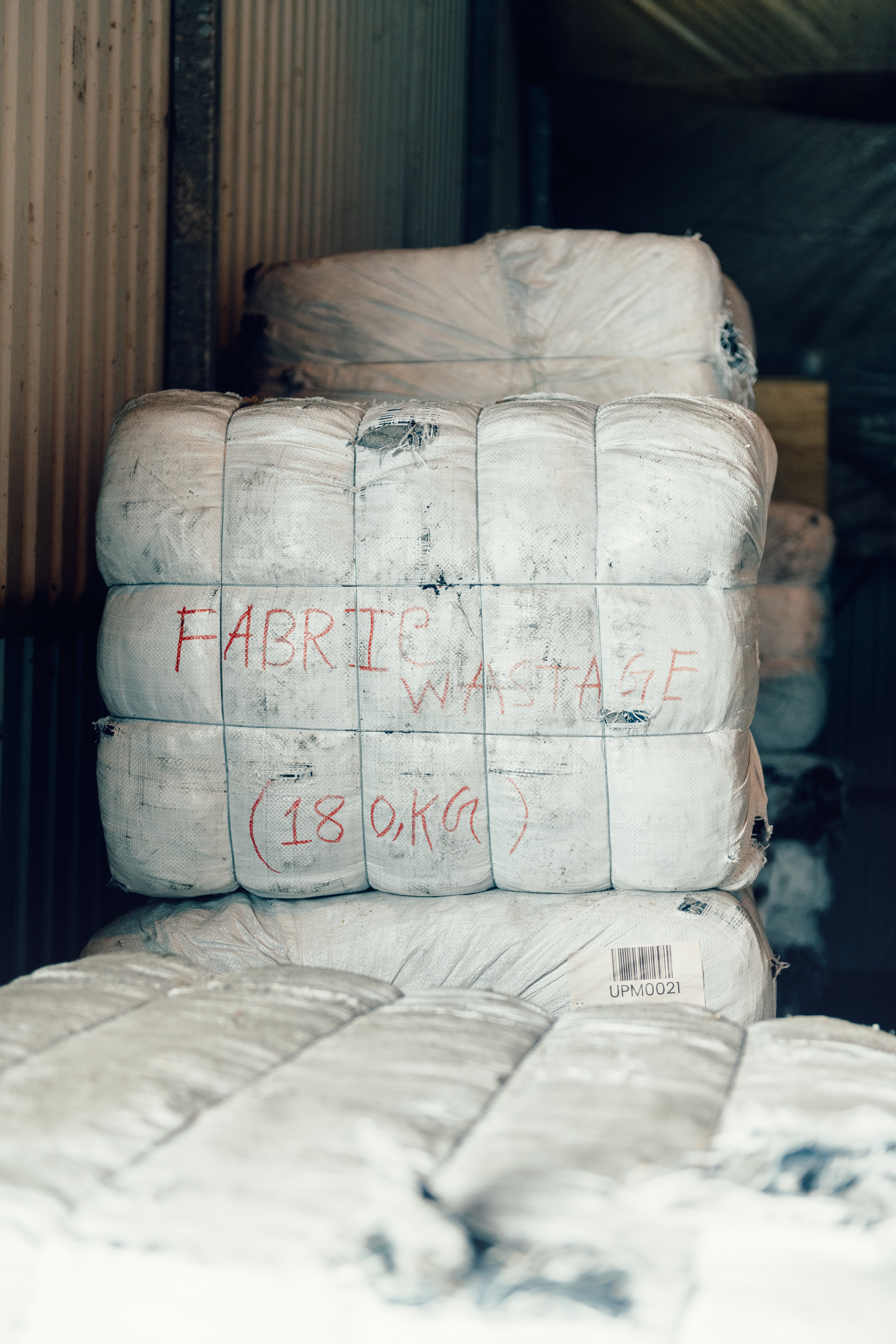

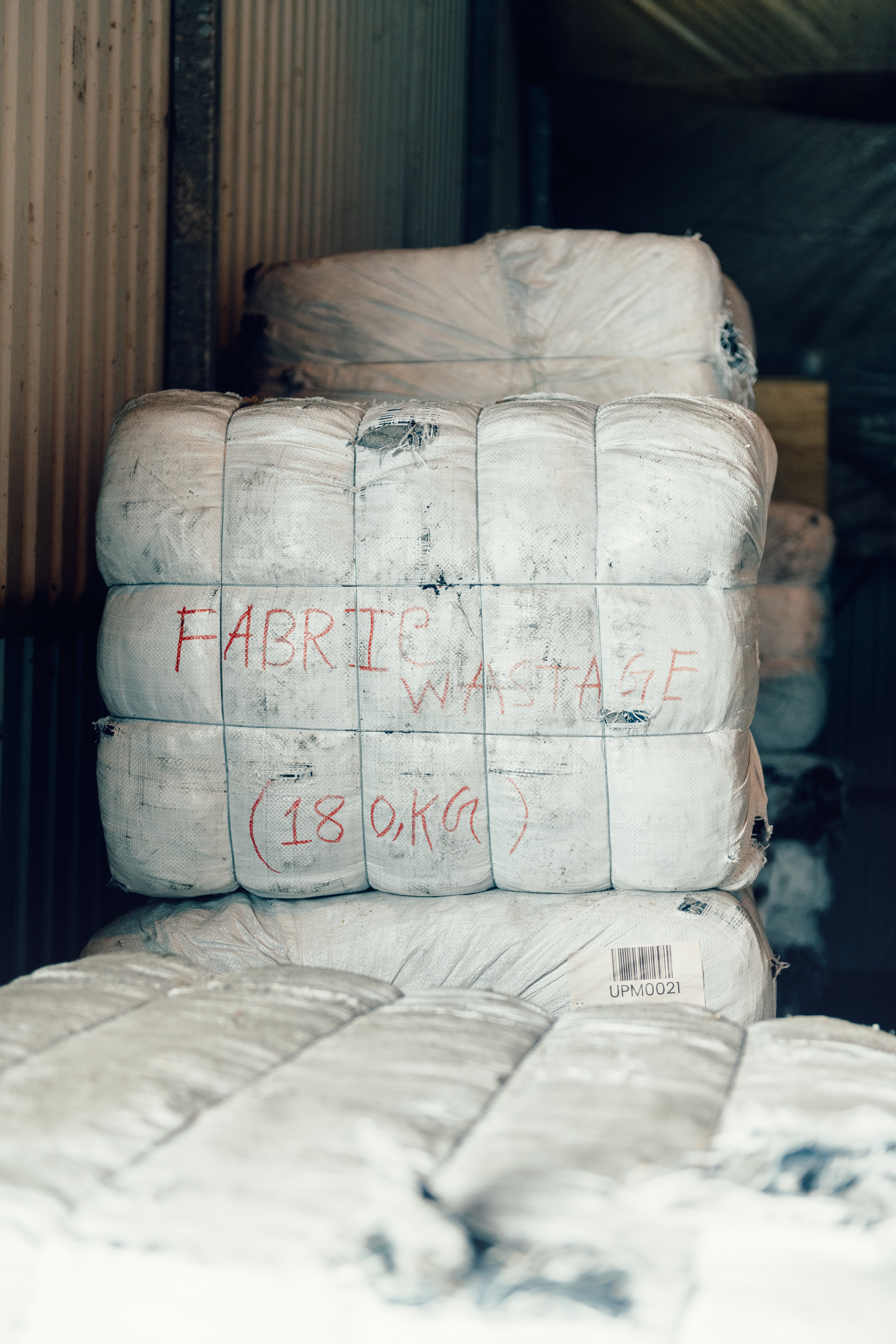

- The continued production of garments containing virgin material is leading to a large amount of textile waste that is not recycled back into textile fibre, a significant portion of which is destined for landfill or incineration;

- The manufacturing process of most MMCFs contains the use of hazardous chemicals, which if not managed correctly using the latest technologies, can harm workers and contaminate local ecosystems.

Current Barriers

Why closing the loop in MMCF production remains a challenge

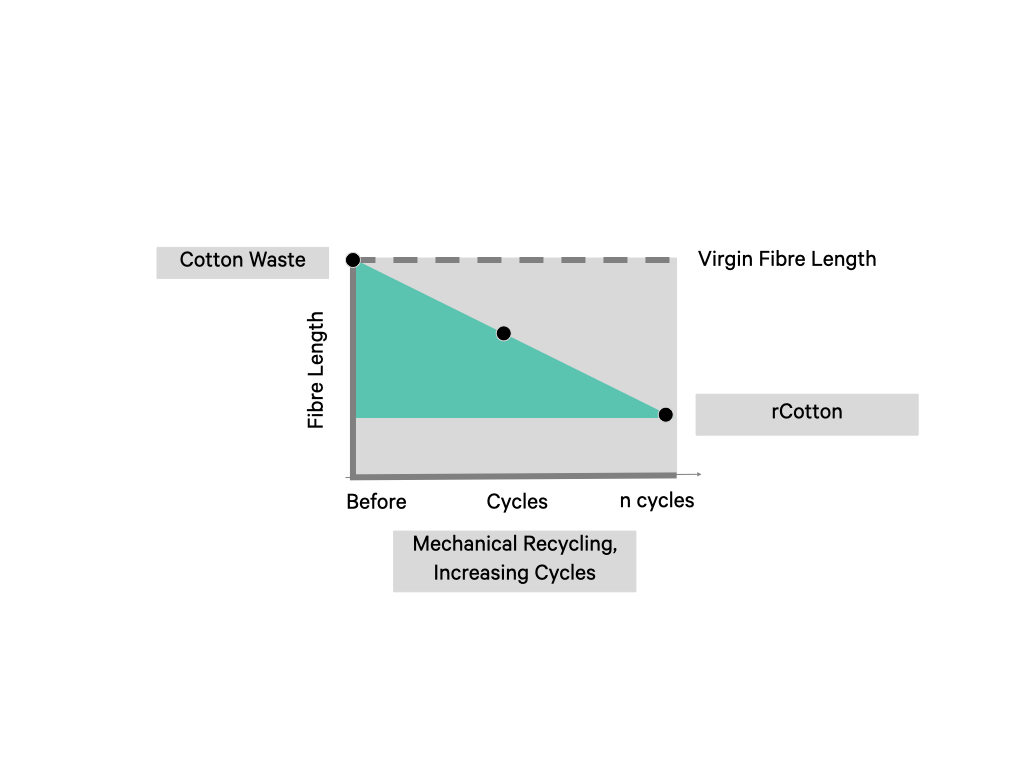

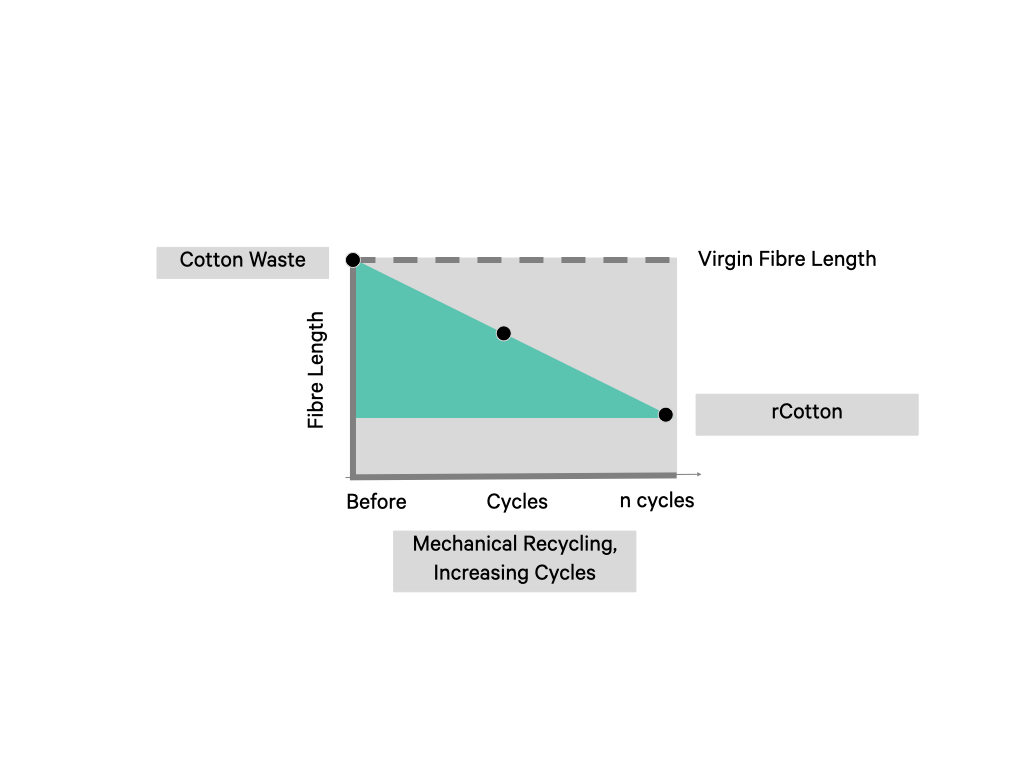

As introduced, the current fashion system is operating in a linear manner of extracting virgin resources and disposing of clothing once it has reached its perceived end-of-life, generating a huge amount of waste. Textile-to-textile recycling holds significant potential to close the loop in MMCF – alleviating the strain on virgin resources (problem 1) and reducing the amount of used textiles going to landfill / incineration (problem 2). Moreover, using cotton waste is more efficient than virgin wood from a yield perspective given the purity of cellulose in cotton. It only requires approximately 1 tonne of cotton waste to generate 1 tonne of cellulosic pulp, compared with 2.5 – 3 tonnes of wood required for the same 1 tonne output30.

A Vision For The Future

A vision for a more sustainable MMCF future system

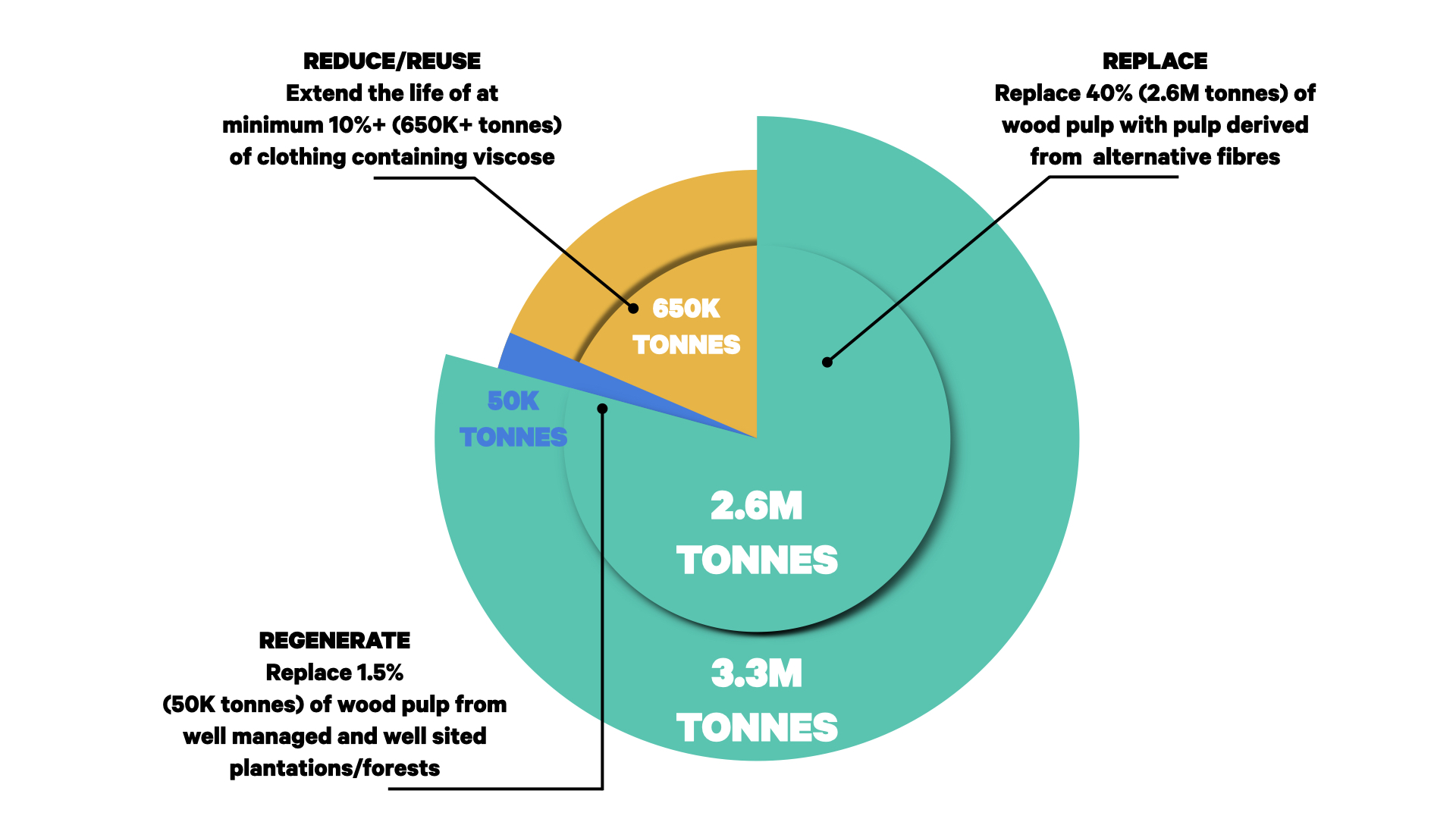

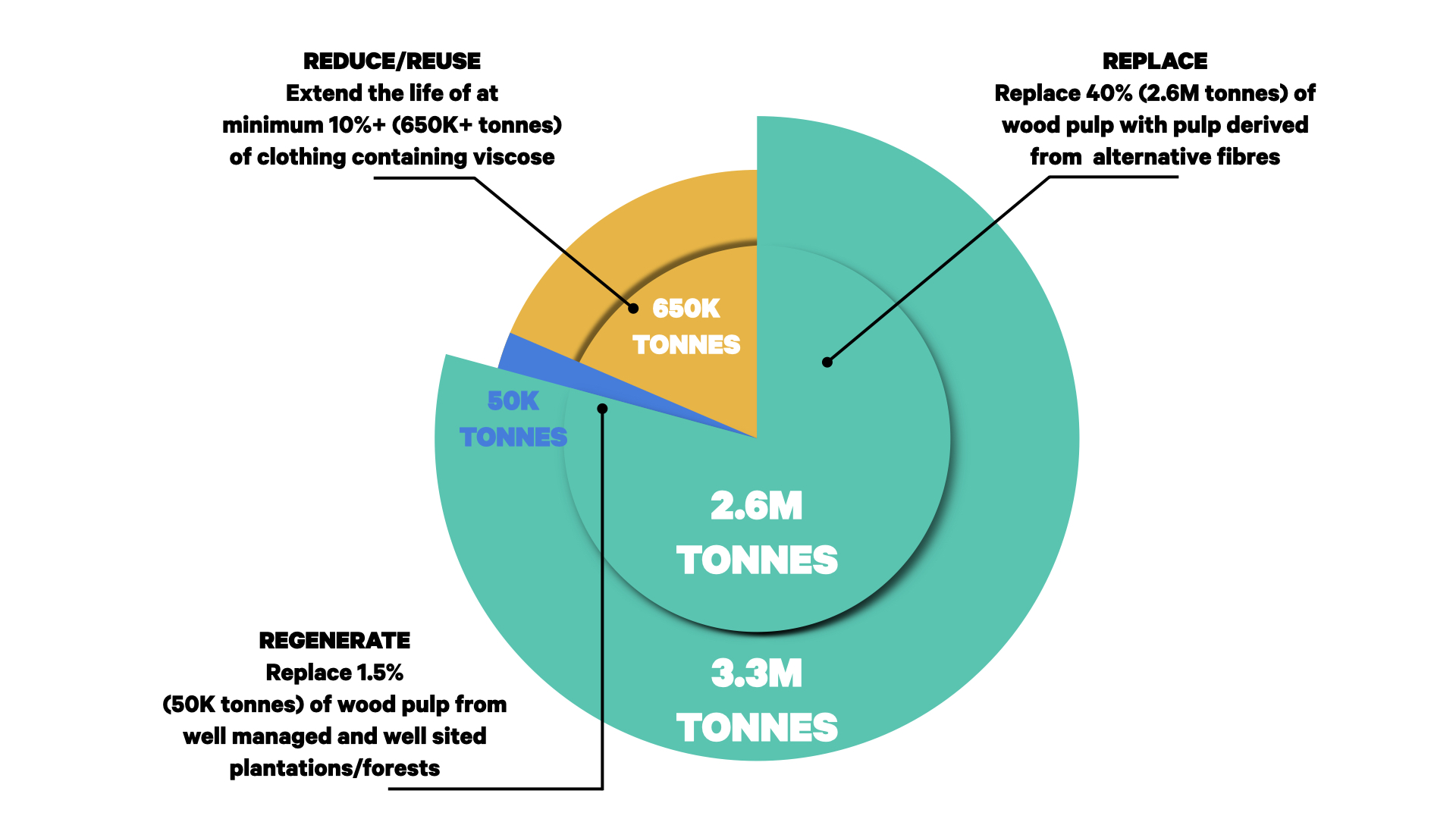

Given the rising importance of MMCFs in the future fashion system, yet the persisting problems of virgin resource depletion and generation of textile waste, it is extremely important that the future value chain transitions to a more sustainable and circular one. There have recently been an emergence of initiatives that aim to address those problems and lay out a vision for a future system – notably Canopy’s Next Generation Action Plan.

Closing The Loop

Disruptive innovation can help to close the loop

The examples of innovation below cover textile recycling technologies and the utilisation of agricultural waste feedstocks in the production of regenerated cellulosic pulp and/or production.

Scaling Up

Consortium projects enable innovation to scale

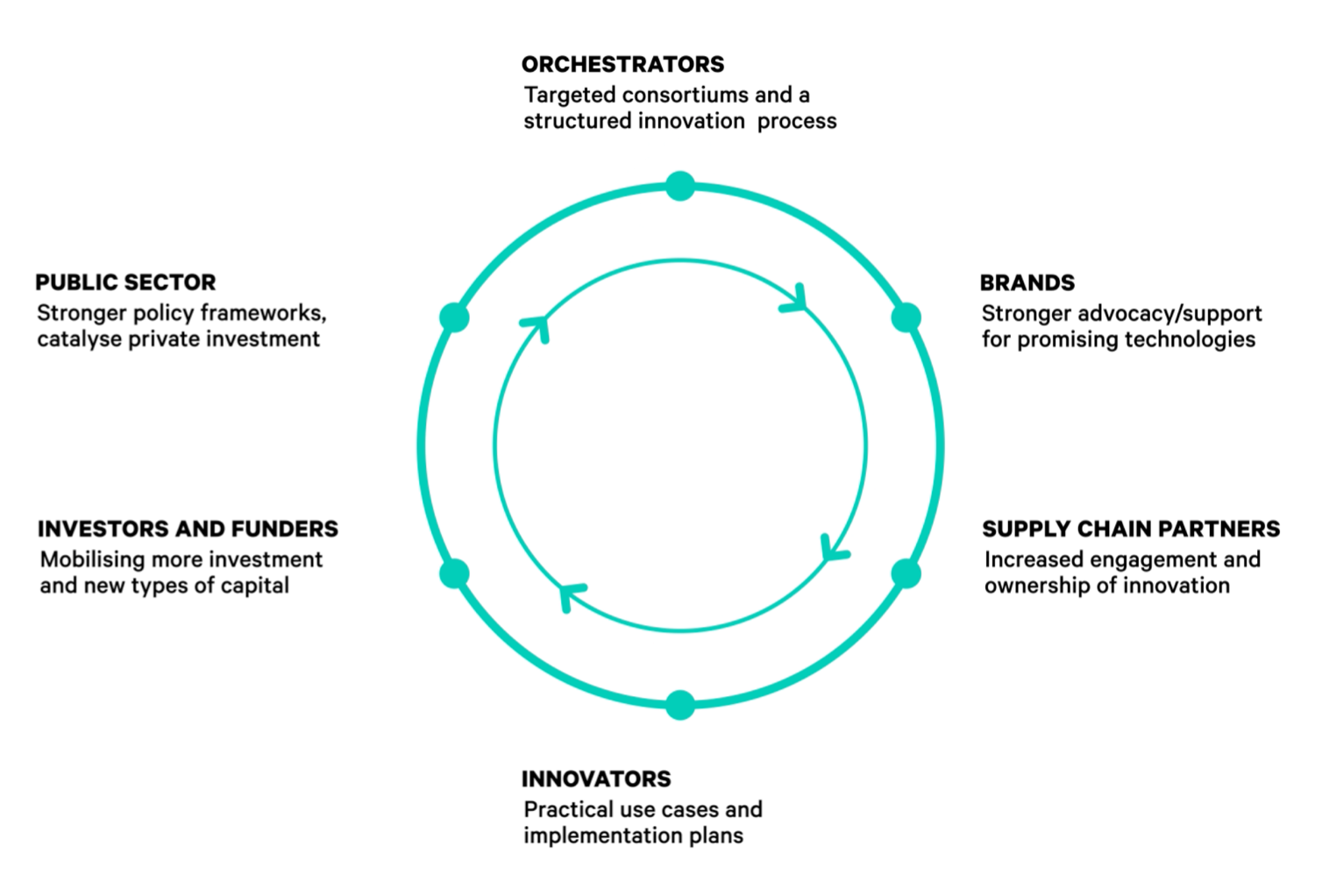

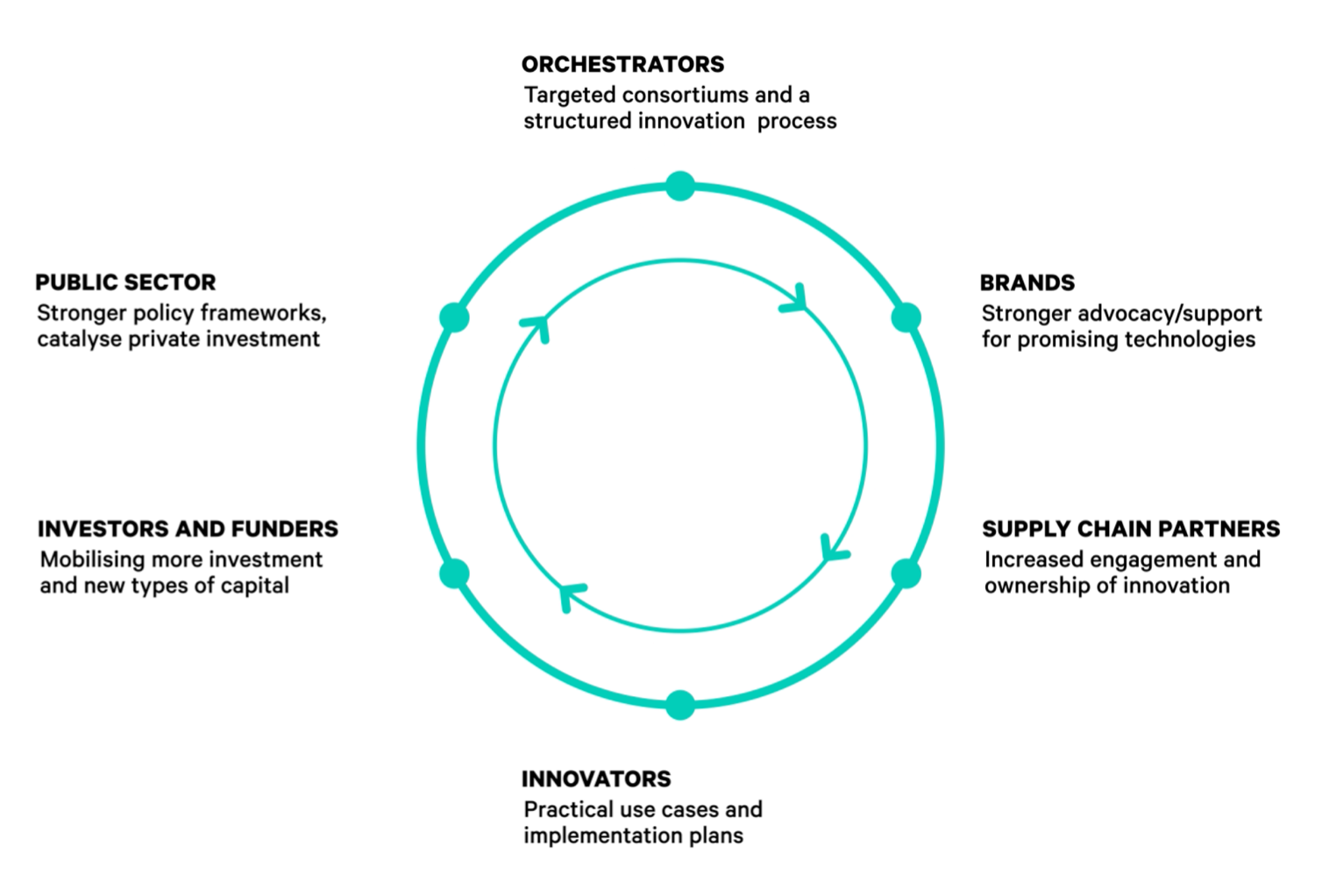

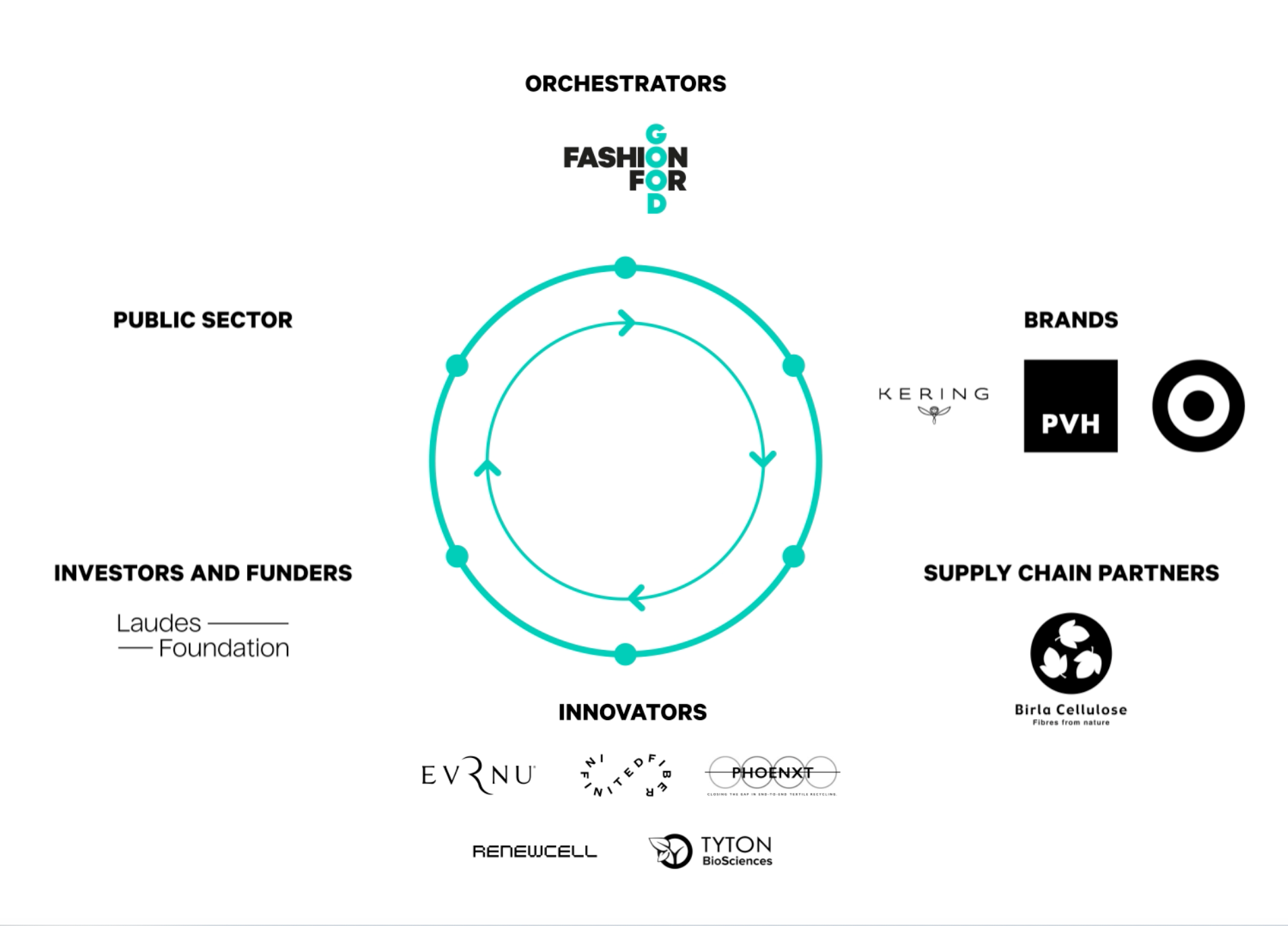

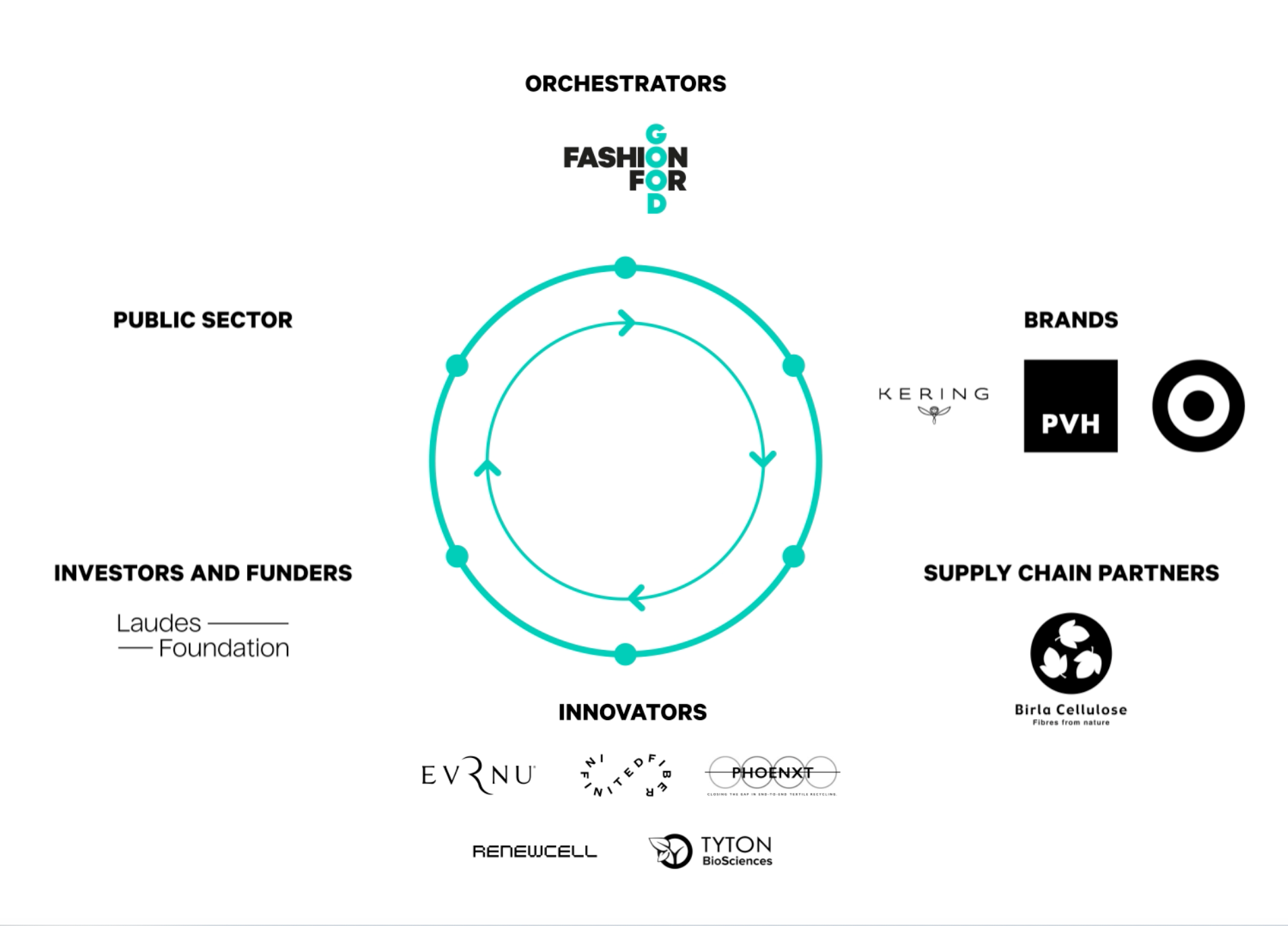

The current fragmented ecosystem of brands, upstream manufacturers and innovators is inefficiently connected and requires greater orchestration to create a marketplace more ready for innovation. Targeted consortium projects and the parties within have the power to convene, accelerate progress and transition from siloed success stories to systemic change70. A recent BCG and Fashion for Good (2020) report outlined the importance of consortium projects in scaling innovation within the fashion industry. The report highlighted several key stakeholders within the consortium group; Orchestrators, Brands, Supply chain partners, Innovators, Investors and the public sector71. This sentiment was echoed within the MMCF industry; with Textile Exchange and Forum for the Future highlighting collaboration across the whole supply chain as a key enabler in the transition to a more sustainable and circular industry72.

Take Action

The full circle textiles project

The aim of the Full Circle Textiles Project is to address the first two problems highlighted in Chapter 3 in this report – that is reducing the amount of textiles going to waste whilst simultaneously alleviating the resource strain on virgin materials through the recycling of used textiles.

Catalysing Transformation

An industry-wide call to action

The MMCF industry currently stands at a critical inflection point; without immediate action the continued irresponsible logging of forests and discharge of hazardous chemicals will damage ecosystems, threaten livelihoods and have irreversible effects on our climate. Having said that, when approached with a path to conserving ancient and endangered forests and circularity in alternative fibre sourcing, MMCF provides an opportunity to divest from oil-derived polyester and water-depleting cotton. Visions for this future system are emerging – mission-driven expert organisations are creating the path for the wider industry to follow. Central to that journey is the scaling of innovation in textile-to-textile recycling. Through this technology, there lies the ability to transform existing textile waste into regenerated fibres of virgin-like quality. This reveals a unique possibility to tackle two of the problem areas with one stone; alleviating the reliance on virgin input and reducing the amount of textile waste being sent to landfill/incineration.

Outcomes and Learnings

Less than 18 months since its launch in September 2020, the Fashion for Good Full Circle Textiles Project has been successfully executed. This final chapter provides an overview of project activities during the two phases, the lessons learnt and finally what lies ahead in scaling these technologies for the future.

Image courtesy of Renewcell