The State of Circular Innovations in the Indian Fashion and Textile Industries

Overarching Supply Chain

There are quite a few topics that are overarching, with impact across the supply chain. This section covers said topics, looking at traceability and transparency, worker empowerment, supply chain redesign and logistics and packaging. Below is a short overview of opportunities in each of these areas.

FOCUS AREAS

SUPPLY CHAIN REDESIGN

Changing the current system of large scale productions in low-cost regions to a system of locally situated micro manufacturers also provides an area of opportunity for innovation. The current supply chain system has, to a large extent, served the consumer well – economies of scale have driven costs down and increased accessibility. However, it has contributed to labour exhaustion, an increased environmental footprint and production delays44.

Alternative solutions have emerged, such as operating a network of small and flexible factories located close to customers. Micro factories operating on a regional level enable production, process and logistics networks to interact in a much more flexible, faster and customised manner. An important part of micro factories is automation, which allows for localisation with lower costs and higher efficiency45. Investing in redesigning the supply chain has a large potential impact on both innovation and sustainability.

Nimbly is an on-demand 3D knitting platform that powers the one-off manufacturing of standard-size garments. Nimbly matches supply with demand, making products in less than an hour – with no order minimums. Nimbly partners with brands, retailers and designers to produce standardised and customised knit creating clothes that are ethically sourced and responsibly produced. Nimbly has the potential to reduce inventory waste with on-demand production. Additionally, true-sizing technology can reduce reverse logistic burdens and waste generated from returns.

WORKER EMPOWERMENT

Workers play a crucial role in the supply chain, it is estimated that a hundred human hands touch a garment during its creation process46. The fashion industry employs around 300 million people across the supply chain47 of which 80% are women48. As a production hub and a labour-intensive geography, worker empowerment is a critical area of innovation in India.

Technological innovations in worker welfare can empower workers. Through various software solutions workers are now able to engage with their employer, report with anonymity, as well as receive training. These solutions become viable alternatives to traditional and manual auditing by giving the workers a medium to engage with others, share opinions and learn about their rights, as a result the workplace can become safer and more efficient.

&Wider has created a cloud platform which enables buyers and employers to hear about workers’ everyday lives and working conditions directly from the workers themselves. The cost-effective diagnostic tools offered by &Wider use mobile phones to track and encourage improvement in labour practices along the supply chain. By using &Wider’s tool, brands and suppliers include workers directly in ethical trade conversations.

LOGISTICS AND PACKAGING

Global supply chains demand long distance transportation and the increasing market share of e-commerce with high return rates requires increased frequency of transportation. Throughout the supply chain there is a high consumption of single use packaging which is primarily made of plastic and cardboard. This contributes significantly to the carbon emissions of the industry, an estimated 5%49 of the total emissions.

If every garment produced per year was shipped in a polybag, there would be more than 180 billion polybags generated each year50. New packaging solutions such as bioplastics, compostable and recycled materials and reusable packaging solutions exist, however no one solution has proven to be a replacement for the traditional materials. This creates an underserved innovation opportunity for the industry.

The Ganges river in India is the second biggest contributor to plastic pollution in the oceans by way of streaming discarded plastic into the open ocean. Additionally, some of the key water bodies in India near Mumbai, Kerala and the Andaman and Nicobar Islands are among the most polluted in the world. Despite these dire environmental consequences, more than half of all the plastic produced is designed to be used only once. In order to improve the current situation, innovative solutions in environment-friendly packaging materials, recycling of packaging materials into new feedstock and circular logistics are required. Fashion for Good for example launched a multi-stakeholder pilot project. The Circular Polybag Pilot explores solutions that aims to reduce the use and impact of virgin polybags in the fashion industry.

Bio-based and biodegradable plastics are often made from feedstocks such as corn or sugarcane and have been adopted for short-term use in product packaging such as the food industry. These can be either ‘drop in’ solutions i.e. direct replacements for existing plastics or require changes in infrastructure to be produced. These bioplastics have the potential to be a good replacement for plastic used in the apparel industry. India is an established market for bioplastics with several manufacturing plants in Bengaluru and Chennai. However there is often confusion between ‘bio-based’ and ‘biodegradable’; not everything bio-based is biodegradable and not everything biodegradable is bio-based. This can lead to challenges around understanding end of life impacts once the bioplastics reach landfill.

Phabio offers biodegradable non-toxic polyhydroxyalkanoates (PHA) as a sustainable alternative to existing polyesters. Phabio’s innovation lies in making biodegradable polymers from renewable biomass obtained as wastage in industries including beer, sugar industry, food waste and seaweed. Phabio uses less water and no chemicals to produce PHA, making it greener than the conventional polyester production. These bioplastics are biocompatible, causing no harm to marine aquatic life or to the environment.

Capturing existing packaging and recycling it back to virgin grade is another prime area for innovation. The Central Pollution Control Board of India estimated the collection efficiency of plastic waste to be 80.28% in 2014, out of which only 28.4% was treated and the remaining quantities were disposed of in landfills or open dumps51. There is a visible uptick in innovations that are redesigning systems and where post-use materials and collected components are being put to other uses. These models aim to incentivise and improve collection and build mechanical and chemical infrastructure to recycle plastic waste.

Lucro is an Indian recycling company that harnesses the possibilities of flexible plastic to produce high quality, innovative and recycled-content products. Lucro specialises in recycling local flexible plastic waste to manufacture recycled-content products. Their Plast-E-CycleTM model helps collect discarded plastic waste through their network of rag-pickers. This waste is further sorted and washed, extruded and granulated to close the loop by producing recycled products. Lucro assists brand owners to redesign and manufacture packaging material to help them shift from virgin material to recycled materials.

WASTEWATER TREATMENT

The dyeing and finishing of textiles represents 20% of global industrial wastewater52, and around 280 000 tonnes per year of dye end up in freshwater53, making treatment of wastewater a priority area for the industry. Conventional treatments, while reducing effluent, generate toxic sludge with chemical discharge and greenhouse gas emissions. Not only is there a high environmental cost but the current systems are also very expensive. Current innovations can be found in the form of microbial fuel cell (MFC) technologies that treat the effluent and convert it into a source of energy.

JSP has developed a microbial fuel cell that generates electricity from the decomposition of textile effluent. Bacteria within the fuel cell breakdown energy rich dissolved solids, releasing energy into a self contained unit that powers itself. JSP recovers water completely while reducing the extensive need of external electricity. The technology is affordable for small and mid scale dyeing units that don’t have common effluent treatment plants.

Another disruptive solution for wastewater treatment is provided by SeaChange Technologies, which separates and oxidises unwanted materials, microplastics and other non-biodegradable components from the water with the help of a powerful jet turbine, releasing only a small amount of CO2 and water vapour. In 2019, Fashion for Good corporate partners Arvind Limited, BESTSELLER, C&A and PVH Corp., came together with support, funding and expertise for a pioneering pilot project with SeaChange technologies. Arvind Limited provided access to their Effluent Treatment Plant near Gujarat, India, one the world’s largest textile manufacturing operations, to conduct a field evaluation. The SeaChange system was implemented over a period of three months to test and evaluate the feasibility of wide scale implementation of the system54. Following this successful pilot, sea-change technologies is now planning and preparing for its commercial launch.

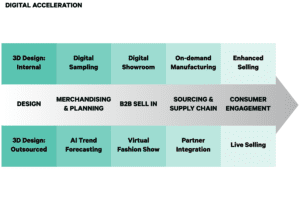

DIGITAL ACCELERATION

Digital solutions can streamline production processes creating efficiencies in design, merchandising and planning, B2B buy-in, sourcing and production as well as in consumer engagement. Some examples include the use of 3D design, digital sampling, AI trend forecasting, digital showrooms, on demand manufacturing as well as enhanced selling.

There are a number of other benefits that come with digitisation throughout the supply chain, including:

- More accurate designs and better communication between designers and manufacturers that can potentially lead to products that are more effectively designed for their purpose;

- Fewer samples, which means less waste;

- The elimination of unnecessary (air)travel;

- Dramatically shorter lead times, which could contribute to limiting overproduction and facilitate on-demand manufacturing;

- And fewer returned items through e-commerce (in the case of digital fitting and virtual try-on).

We have explored the opportunities for digital acceleration throughout the fashion value chain highlighting the innovations that are driving the transformation.

FIGURE 7

3D Design

Historically prototypes and samples would go through multiple iterations and physical prototypes before the final product is signed off. 3D design means designers can see the garment instantly. In addition to this, it also allows for real-time feedback on the cost and in the near future also the impact of the garment. It enables more effective communication between teams and between brands and manufacturers. Solutions also exist that enable the digitisation of real fabrics, that can then be saved and uploaded into 3D design software. The 3D design process can be implemented internally or outsourced to third party companies. Whilst the latter might be quicker in the short-term, the advantages of digitising one’s own internal workflow allows brands and manufacturers to reap the benefits.

Swatchbook is a cloud platform revolutionising the exploration, visualisation and sharing of materials. The platform enables suppliers to upload their materials along with other metadata and pricing details for brands to further explore, discover and visualise materials, sharing them with other stakeholders for further use.

Merchandising and Planning

Following the design phase, merchandisers can then compile the final collection using these digital samples. They can be more easily distributed throughout the company and reduce lead times. This in turn allows for better trend forecasting. In addition, many start-ups and established players are developing advanced AI trend prediction solutions that help brands to better understand their consumers and their needs.

B2B Sell in

Digital showrooms enable brands and manufacturers to showcase their digital collections in a virtual space. With reduced travel in a post COVID-19 world, this enables both brands and manufacturers to continue to drive customer relationships. These showrooms actually allow stakeholders to go above and beyond the usual experience bringing the garments to life through different platforms and technologies such as Virtual Reality (VR) or using 3D assets.

Sourcing and Production

As mentioned before, brands as well as manufacturers work with 3D software which can be used as a real-time feedback and communication platform. As such, it’s important for brands to onboard their manufacturing partners to ensure they are achieving consistent quality together. The ultimate goal is to create 3D models that remove the need for tech packs, where manufacturers could cut and sew products using only these 3D models.

Digital samples also help facilitate on demand manufacturing as customers can see photo-real images early on in the process.

Customer Engagement

Alongside supply chain solutions there are many technologies that allow brands to engage with consumers in new ways. Some examples of these include AI style and fit solutions, virtual fashion try on, Extended Reality (XR) shopping and live selling.

AI style and fit advisors allow brands to provide better recommendations to consumers, reduce e-commerce returns and drive conversion. Virtual fashion try-on uses Augmented Reality (AR) to allow consumers to virtually try on garments before they buy. Whilst XR shopping means they can shop virtually from wherever they are in the world. Finally, live selling allows brands and retailers to reach new markets or audiences using store associates or celebrities.

While still a niche space, the application of VR and AR technologies for e-commerce and retail appears to be the “next big thing” in the world of sustainable shopping.

TRANSPARENCY AND TRACEABILITY

Transparency in the supply chain means the standardised disclosure of relevant information at each step creating a common understanding, accessibility, clarity and comparison55. Traceability on the other hand, is defined as the process by which materials and products are tracked as well as the conditions in which they were produced throughout the entire supply chain56. Traceability is an indispensable prerequisite leading to increased transparency and ultimately accountability by enabling brands to address environmental and social sustainability impacts through identification of such pain points along the supply chain.

Transparency and traceability solutions are challenged by the complexity of global textile supply chains which are characterised by a lack of integration among the numerous actors. This is made more acute by the growing number of standards without a unified, industry-wide solution that is easily implementable. Furthermore, the ambiguous link of traceability to firm performance, perceived risk of disclosing certain data and the unclear business case gives companies limited incentives to incorporate traceability into their strategy. Currently, only a third of the industry traces the supply chain beyond Tier 257. While significant environmental impact takes place in Tier 1 and 2, there is an increased consumer and stakeholder demand as well as evolving laws and regulations forcing companies to re-evaluate their efforts.

The Indian textile and apparel industry is notoriously opaque as garment supply chains are highly fragmented, difficult to trace and environmentally inefficient. In a crowded marketplace like India which is also one of the top garment exporters in the world, transparency is required in order to stay competitive.

The most interesting traceability projects combine blockchain technologies, tracers and communication platforms. Blockchain technology is a type of distributed ledger system for maintaining a permanent digital and tamper-proof record of transactional data. Tracers are product marking and identification tools. There are various types of tracers that can be integrated with blockchain technology to enable traceability. DNA, fluorescent particles and microparticle analysis are some of the new tracers being applied in the textile industry; for more details see the Organic Cotton Traceability Pilot, convened by Fashion for Good and Organic Cotton Accelerator58. To communicate the information stored in a blockchain, tools such as hang-tags including QR codes, benchmarking and auditing platforms are used. Beyond ensuring security and authenticity of data, blockchain-based innovations are also aiming to ensure data exchange by enhancing compatibility and the ability to integrate with existing systems used by stakeholders across the supply chain.

TrusTrace provides brands such as Filippa K, Decathlon and the Fenix Group, with a blockchain-based software platform for tracing their supply chain from fibre to garment. Through TrusTrace, users have been able to seamlessly identify the raw materials at a LOT level, collect and validate product and facility certifications, compute the product footprint and communicate the product story to the end customers. The information is used by brands to communicate this information to their customers, perform internal risk analysis and manage their supply chain better.